Milling Tools

-

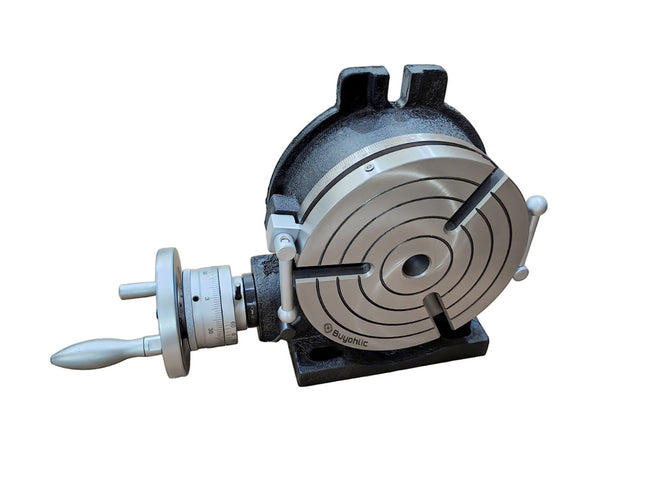

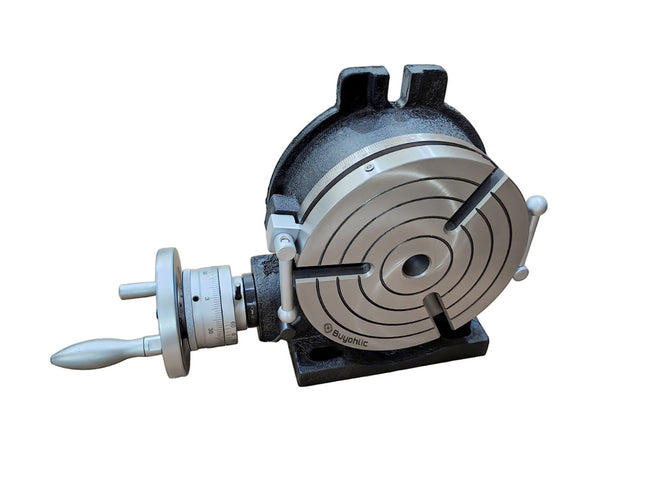

Small HV 3" Inch II 80 mm Rotary Milling Tables

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. Key Features: Compact & Low-Profile Design: Table Diameter: The rotary table features a 3-inch (80 mm) diameter, making it perfect for small-scale milling operations where space and precision are critical. Vertical Height: With a vertical height of just 1-5/8 inches, this rotary table maintains a low profile, enabling it to fit seamlessly into your existing setup while maximizing available workspace. Precision Engineering: Gear Ratio: The rotary table boasts a 36:1 gear ratio, ensuring precise control over the rotation. One full rotation of the handle results in a 10-degree rotation of the table, allowing for meticulous adjustments during milling tasks. Scale Calibration: The table scale is finely calibrated in 5-degree increments, providing clear and accurate angle measurements. This feature is particularly useful for tasks requiring high precision and consistency. Versatile Positioning: Horizontal & Vertical Use: This rotary table is designed for maximum versatility, capable of operating in both horizontal and vertical positions. This dual functionality allows for a wide range of applications, from simple flat milling to more complex angular cuts. Robust Construction: Base Dimensions: The base of the rotary table measures 4-1/8" x 3-1/4", providing a stable and secure platform for your work. The compact dimensions ensure that the table remains sturdy during use, minimizing vibrations and enhancing accuracy. T-Slots: The base is equipped with four 5/16" T-slots, allowing for secure clamping of workpieces. These slots are designed to accommodate various clamping setups, ensuring your workpiece remains firmly in place throughout the milling process.

$35.99 - $65.90

-

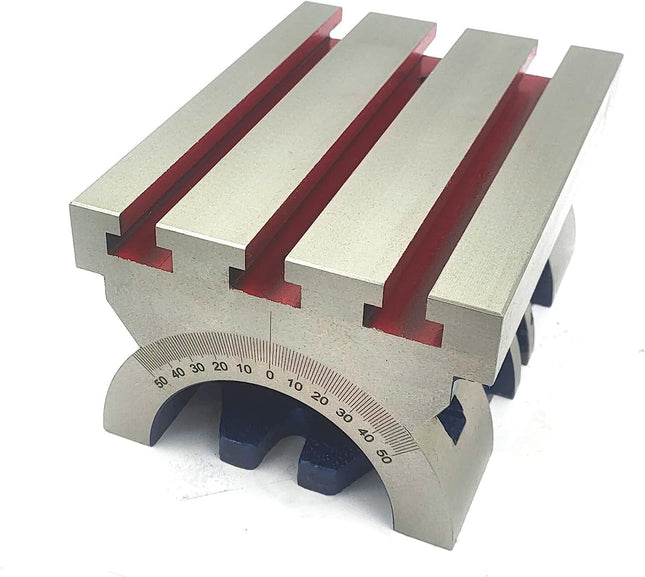

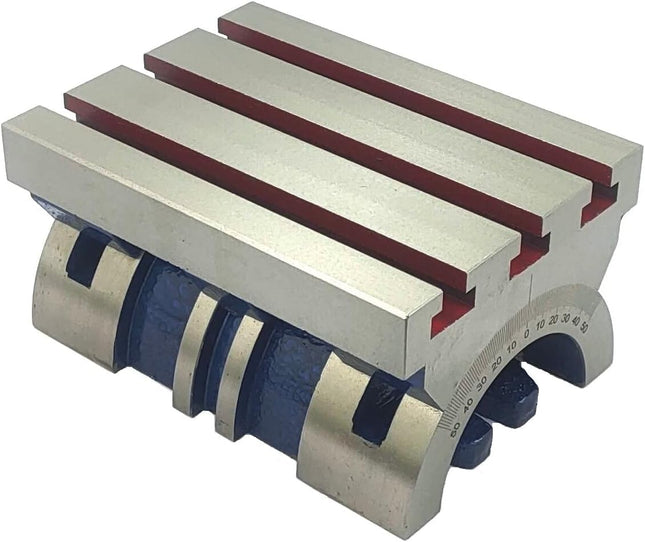

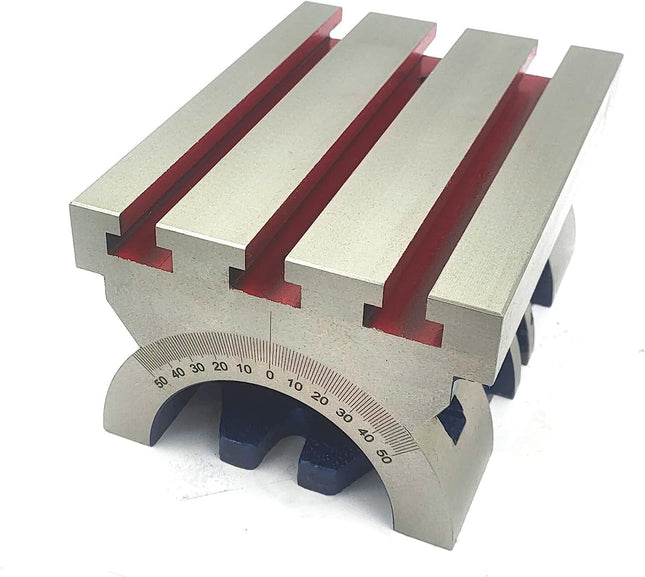

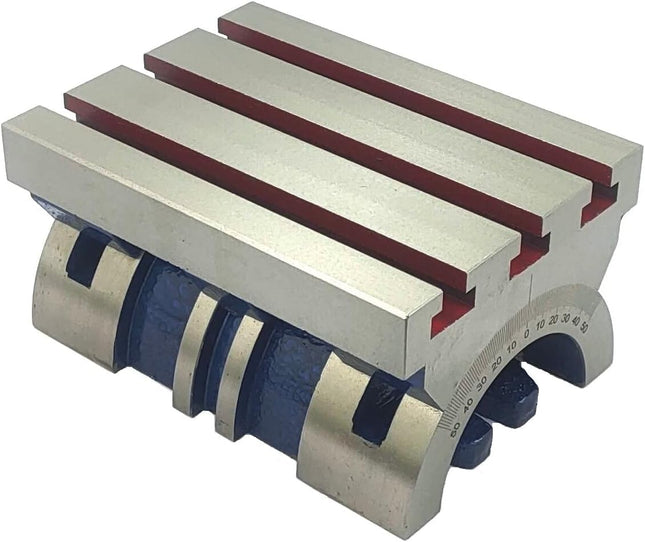

Tilting Table for Milling Machine

High-Precision Tilting Table for Milling Machines Use of product- A tilting table for a milling machine is an accessory that provides angular positioning for workpieces. It is used to tilt the workpiece to a specific angle, allowing for machining operations that require angled cuts, such as beveling, chamfering, and creating complex geometric shapes. Enhance your machining capabilities with our High-Precision Tilting Table, designed to deliver superior accuracy and versatility for your milling operations. Key Features: Adjustable Angle Range: Achieve precise angular positioning with a tilting range of 0° to 45°, perfect for beveling, chamfering, and complex angle cuts. Precision Scale: Features a clearly marked scale and adjustable stops for easy and accurate angle settings, ensuring repeatable precision. Sturdy Construction: Built from high-quality cast iron, this tilting table provides exceptional durability and stability, reducing vibrations and enhancing machining accuracy. Smooth Operation: Equipped with precision-ground ways and a high-quality lead screw for smooth and effortless angle adjustments. Versatile Mounting: Compatible with most milling machines, the tilting table includes multiple mounting slots for secure and flexible attachment of workpieces. Enhanced Productivity: Reduces the need for multiple setups, saving time and increasing efficiency in your machining processes. Applications: Ideal for creating angled cuts and complex geometric shapes. Perfect for precision engineering tasks in aerospace, automotive, and metalworking industries. Suitable for both professional workshops and hobbyist machinists seeking to expand their capabilities. Specifications: Material: High-quality tool steel Tilting Range: 45- 0-45 Degrees Table Size: 4" X 5" Inches/ 100 X 125 mm & 5" X 7" Inch / 125 X 175 mm For 4" x 5" Height in Horizontal Position 80 mm and for 5" x 7" is 90 mm Neatly Machined T Slots. Why Choose Our Tilting Table? Unmatched Precision: Ensure every cut is exact with our meticulously designed scale and adjustment mechanism. Robust Build: Count on a tilting table that withstands the rigors of daily use while maintaining top performance. Ease of Use: Simple adjustments and a user-friendly design make it easy to integrate into any milling setup. Upgrade your milling machine today with our High-Precision Tilting Table and experience a new level of accuracy and efficiency in your machining projects. Order now and take your craftsmanship to the next level!

$89.90 - $107.90

-

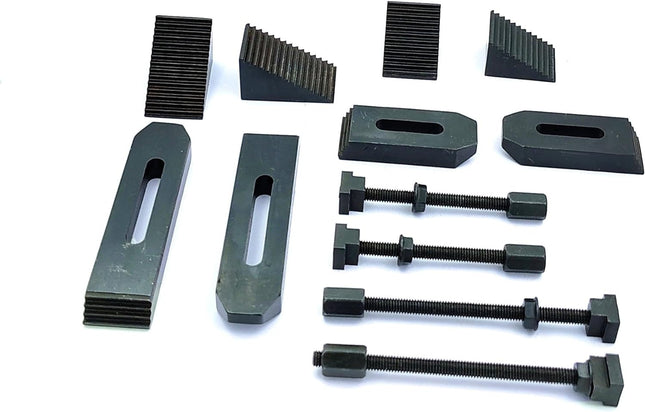

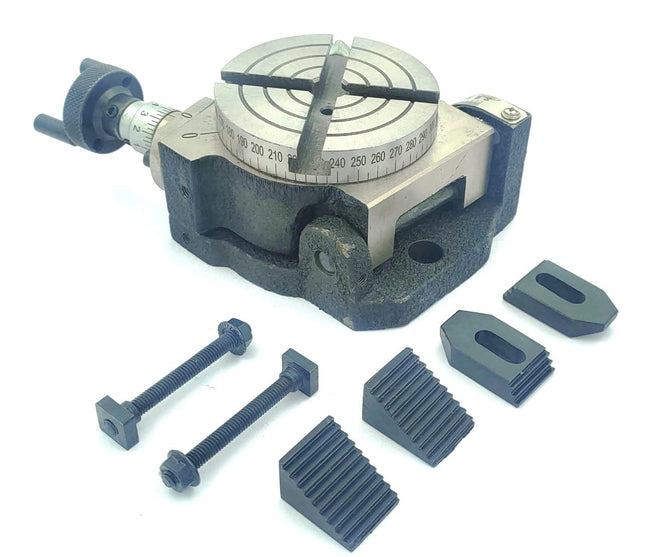

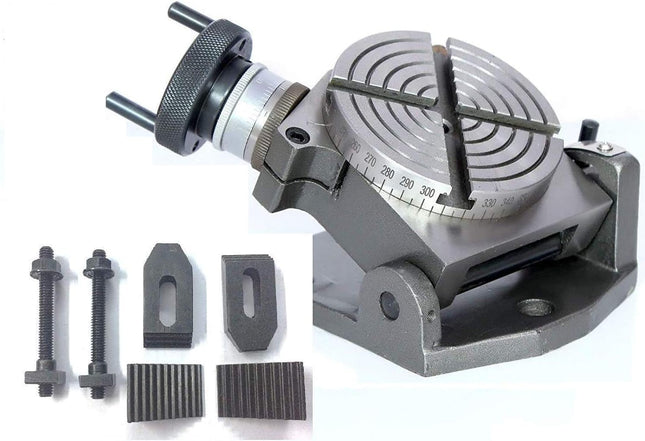

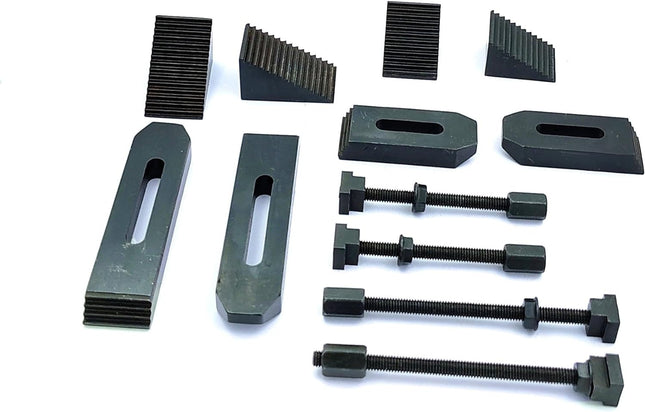

Clamp Kit For Rotary Table

Use of Product- A clamp kit for a rotary table is used to secure workpieces onto the rotary table during machining operations. Rotary tables are often used in machining setups to enable circular cutting, hole drilling, and other operations around a fixed axis of rotation. Clamp kits typically consist of various clamps, bolts, nuts, and T-slot nuts designed to fit the T-slots or other mounting features on the rotary table. These components allow you to securely fasten the workpiece to the rotary table, ensuring it stays in place during machining. M6 Clamp Kit for 3"/4" Rotary Table:- This M6 clamp kit is designed for use with 3" or 4" rotary tables. Includes a set of clamps, bolts, nuts, and T-slot nuts. Compatible with rotary tables featuring M6 T-slots or mounting holes. Allows for secure fastening of workpieces onto the rotary table during machining operations. Made of tool steel for durability and reliability. Provides essential holding power to maintain precision and accuracy. Ideal for use in machining setups requiring precise rotary table positioning. M8 Clamp Kit for HV4/HV6 Rotary Table:- Specifically designed M8 clamp kit for HV4 or HV6 rotary tables. Consists of clamps, bolts, nuts, and T-slot nuts tailored for M8 T-slots or mounting features. Enables secure attachment of workpieces onto the rotary table for machining operations. Crafted from premium materials to ensure longevity and performance. Compatible with a wide range of machining setups requiring HV4 or HV6 rotary tables. Essential accessory for maintaining precision and stability during rotary table machining. Suitable for various metalworking applications, including milling, drilling, and more. 24 Pcs Clamp Kit Set M6 (6 mm):- Quality Clamping Kit set of 24 Pieces- M6 Thread Standard. Epoxy Black Finish for a long Rust Free Life 24 Piece Clamping Kit set Has a wide variety of clamping applications on Face Plates, Cross Slides, Milling Beds & Vertical Slides. Set Includes :- 4 Tee Nuts 8mm,6mm thread, 4 flanged nuts 6mm thread, 4 coupling nuts 6mm thread, 2 studs 6mm thread 80mm long, 2 studs 6mm thread 100mm long. 1 pair of step blocks, 1 pair of small step clamp,1 pair of large step clamp. Application- Suitable for use with Bridgeport mills and other milling machines, ideal for holding down workpieces securely and accurately. Easy to Use- Designed for easy installation and removal, allowing for quick and hassle-free use.

$18.90 - $40.50

-

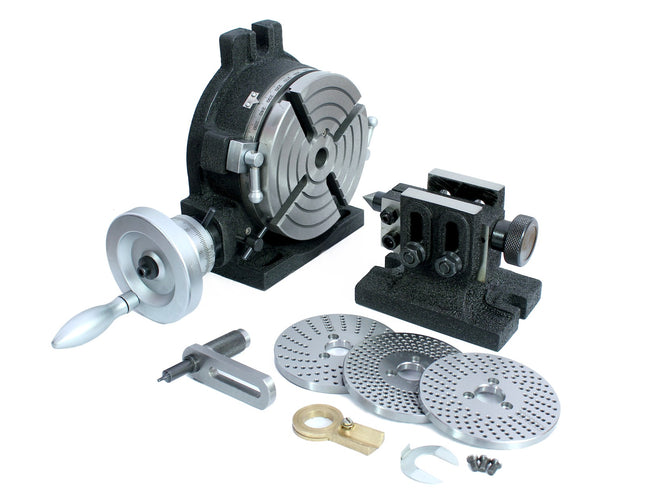

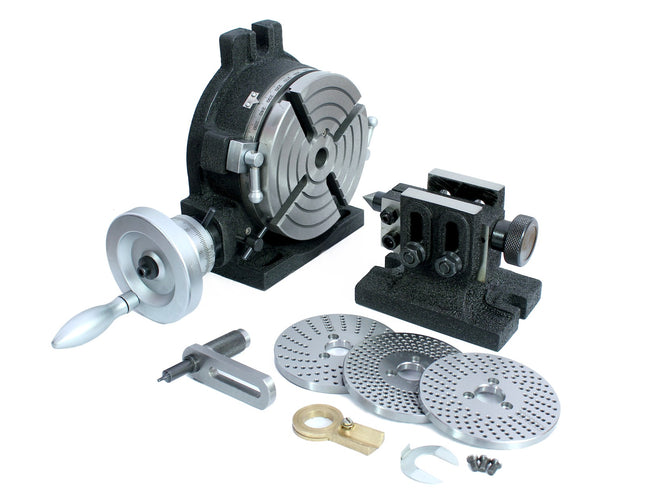

HV6 Rotary Table 4 Slot 6" 150 mm With Tailstock & dividing Indexing Plates Set

A rotary table is a precision tool used predominantly in metalworking, particularly in machining operations like milling and drilling. Its primary function lies in enabling machining at precise angular intervals around a fixed point, commonly referred to as indexing A tailstock, also known as a foot stock, is a device often used as part of an engineering lathe, wood-turning lathe, or used in conjunction with a rotary table on a milling machine. It is usually used to apply support to the longitudinal rotary axis of a workpiece being machined. When mounted onto a rotary table, which is a precision workholding device that allows for precise positioning of workpieces, the dividing plate helps in accurately dividing the rotation of the table into equal parts. This division is crucial for tasks like cutting gears, splines, or other components that require precise angular spacing or indexing. HV6 Rotary table Gear Ratio: 90:1 gear ratio for efficient table movement, with each handle rotation shifting the table by 4 degrees, enabling precise control. Center Bore: Equipped with a Center Bore MT-2 and a 16 mm T-slot, ensuring seamless compatibility and secure clamping. Versatile Clamping: Can be clamped both vertically and horizontally to accommodate diverse workpiece orientations. Dimensions: The horizontal height is approximately 80mm from the base to the top surface of the chuck, ensuring stability and ease of use. In the vertical position, the center height is 105mm, providing ample clearance for machining operations. Graduations: The table is graduated 360 degrees around its circumference, with a resettable dial and a handwheel graduated in seconds for precise angular adjustments. Lubrication: Equipped with two oiling points for direct lubrication, enhancing the rotary table's longevity and performance. Comprehensive Solutions: Our store offers a range of compatible accessories, including dividing plates, tailstocks, chucks, and clamp kit sets, for a complete machining solution. Tailstock for HV6 Rotary Table Heavy Duty Construction: Built to last with tool steel, providing stability and support for your machining tasks. Adjustable Height: Easily adjust the height to accommodate different workpieces and machining requirements. Versatile Compatibility: Available in various sizes compatible with 3" / 4" rotary tables as well as HV4/HV5/HV6/HV8 rotary tables, ensuring compatibility with a wide range of setups. Smooth Operation: Ensures smooth and precise performance, enhancing the accuracy of your machining operations. Easy Installation: Designed for hassle-free installation, allowing you to quickly set up and start machining. Enhanced Stability: Provides a solid foundation for your workpieces, minimizing vibration and ensuring consistent results. Wide Application: Suitable for various machining tasks, from milling to drilling, turning, and more. Essential Accessory: A must-have addition to your rotary table setup, enhancing its functionality and versatility for diverse machining projects. Professional Quality: Designed for professional machinists and hobbyists alike, offering reliability and performance you can trust. Available in Different Sizes: Choose the size that best fits your rotary table setup, ensuring a perfect fit and optimal performance. Tailstock HV4/ HV5/ HV6- Minimum Center Height 80 mm & Maximum Center Height is 105. Base Dimension 135 mm x 90 mm/ Dividing Plates Set for HV4 /HV6 Rotary Table: Set Includes: 3 x Indexing Dividing Plate and accessories. Diameter of the Plates is 100 mm. Centre Hole of the Plate is 21 mm. Thickness 7 mm Plate 1 – 15, 16, 17, 18, 19, 20 Plate 2 – 21, 23, 27, 29, 31, 33 Plate 3 – 37, 39, 41, 43, 47, 49

$320.00 $289.99

-

Buyohlic Horizontal Vertical HV8 8" (200 mm) -3 slots Rotary Milling Indexing Table

A rotary table is a precision tool used predominantly in metalworking, particularly in machining operations like milling and drilling. Its primary function lies in enabling machining at precise angular intervals around a fixed point, commonly referred to as indexing. This capability facilitates the creation of intricate geometries, circular features, and multi-sided machining without the need for manual repositioning of the workpiece. By mounting the workpiece on the rotary table and rotating it, machinists can execute complex operations such as gear cutting, spiral grooving, and helical cuts with high precision. Additionally, rotary tables are essential for tasks requiring circular or arc-shaped machining, offering versatility and efficiency in manufacturing processes. Upgrade your machining capabilities with our HV8 Rotary Table, designed for high precision and durability. Ideal for both professional and hobbyist applications, this rotary table is built to handle diverse machining tasks with ease and accuracy. Key Features: Disc Diameter: 200 mm - Optimized for a wide range of setups and part sizes. Turbine Worm Speed Ratio: 1:90 - Ensures smooth, controlled rotation, perfect for precision work. Vertical Center Height: 135 mm - Accommodates varied machining needs, making it a versatile addition to your setup. Weight: 30 kg - Stable and robust, it minimizes vibrations, enhancing accuracy. Built to Last Constructed with premium materials, this HV8 rotary table withstands heavy-duty use while maintaining consistent, reliable performance. Its 3-slot design allows for secure, versatile clamping of workpieces, ensuring ease of use across various machining applications. Precision & Versatility The 1:90 gear ratio provides precise control over positioning, making it well-suited for detailed work that requires accuracy. The compact yet sturdy design fits seamlessly into your workspace, allowing for flexibility whether working on vertical or horizontal setups. Ideal Applications: Perfect for milling, drilling, and even more complex operations like engraving or machining circular parts.

$380.00 $325.00

-

4"/ 100 mm Regular Rotary Table With Small Chucks and back Plate

Use of product- A rotary table is used to rotate a workpiece precisely during machining, allowing for accurate creation of circular features, angles, and indexing tasks. A chuck is used to securely hold and grip a workpiece on a machine tool, ensuring it remains stable and aligned during operations like turning, drilling, or milling. 4"/ 100 mm Rotary Table Very High Quality 4" /100 mm Regular Rotary Table designed for smaller milling machines Table is graduated 360 Degrees. Worm Gear Ratio -1:36, which means that the 1 handle rotation shall turn the table by 10 Degrees. Center Height in vertical position: 2-1/16" (50 mm approx) Hand wheel is graduated in divisions of 10 min & can be set to zero. Can be mounted both in Horizontal & vertical position. Chuck 65 mm 3 Jaw Self Centering Precision 65mm 3-Jaw Self-Centering Lathe Chuck Compatible with M14 x 1 mm threading Chuck 70 mm 4 Jaw Independent Precision 70 mm 4-Jaw Independent Lathe Chuck Compatible with M14 x 1 mm threading M6 Clamp Kit This M6 clamp kit is designed for use with 3" or 4" rotary tables. Includes a set of clamps, bolts, nuts, and T-slot nuts. Compatible with rotary tables featuring M6 T-slots or mounting holes. Allows for secure fastening of workpieces onto the rotary table during machining operations. Made of tool steel for durability and reliability. Provides essential holding power to maintain precision and accuracy.

$139.90 - $157.99

-

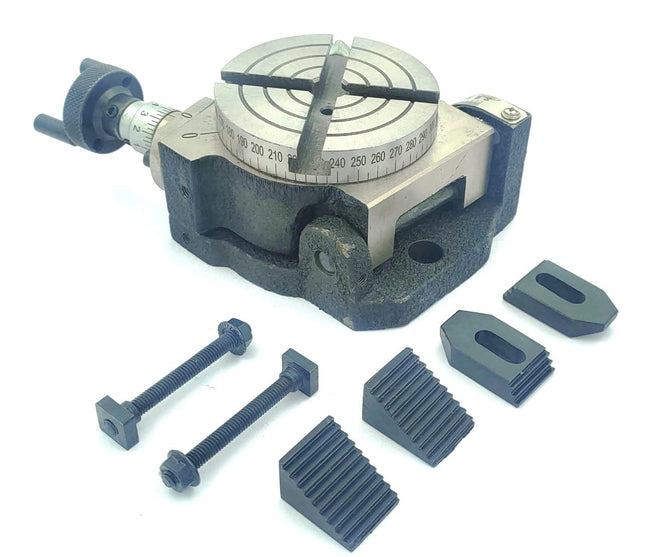

Small HV 3" Inch II 80 mm Rotary Milling Indexing Table with Clamp Kit

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. A clamp kit for a rotary table is used to secure workpieces onto the rotary table during machining operations. Rotary tables are often used in machining setups to enable circular cutting, hole drilling, and other operations around a fixed axis of rotation. Key Features: Compact & Low-Profile Design: Table Diameter: The rotary table features a 3-inch (80 mm) diameter, making it perfect for small-scale milling operations where space and precision are critical. Vertical Height: With a vertical height of just 1-5/8 inches, this rotary table maintains a low profile, enabling it to fit seamlessly into your existing setup while maximizing available workspace. Precision Engineering: Gear Ratio: The rotary table boasts a 36:1 gear ratio, ensuring precise control over the rotation. One full rotation of the handle results in a 10-degree rotation of the table, allowing for meticulous adjustments during milling tasks. Scale Calibration: The table scale is finely calibrated in 5-degree increments, providing clear and accurate angle measurements. This feature is particularly useful for tasks requiring high precision and consistency. Versatile Positioning: Horizontal & Vertical Use: This rotary table is designed for maximum versatility, capable of operating in both horizontal and vertical positions. This dual functionality allows for a wide range of applications, from simple flat milling to more complex angular cuts. Robust Construction: Base Dimensions: The base of the rotary table measures 4-1/8" x 3-1/4", providing a stable and secure platform for your work. The compact dimensions ensure that the table remains sturdy during use, minimizing vibrations and enhancing accuracy. T-Slots: The base is equipped with four 5/16" T-slots, allowing for secure clamping of workpieces. These slots are designed to accommodate various clamping setups, ensuring your workpiece remains firmly in place throughout the milling process. M6 Clamp Kit This M6 clamp kit is designed for use with 3" or 4" rotary tables. Includes a set of clamps, bolts, nuts, and T-slot nuts. Compatible with rotary tables featuring M6 T-slots or mounting holes. Allows for secure fastening of workpieces onto the rotary table during machining operations. Made of tool steel for durability and reliability. Provides essential holding power to maintain precision and accuracy. Ideal for use in machining setups requiring precise rotary table positioning.

$67.99 - $89.99

-

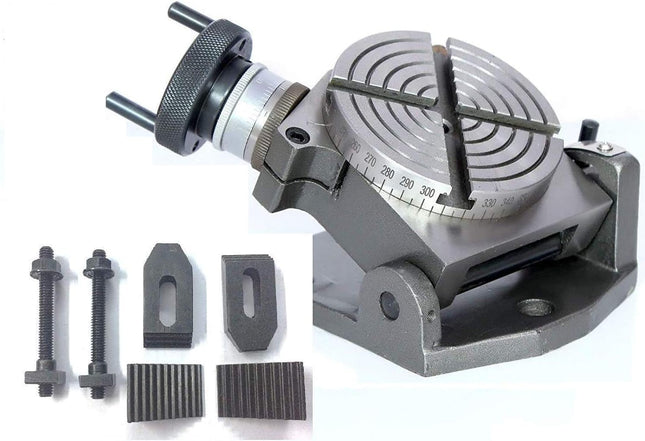

Horizontal Vertical 4" Inch II 100 mm Rotary Milling Indexing Table with M6 Clamp Kit

A rotary table is a precision tool used predominantly in metalworking, particularly in machining operations like milling and drilling. Its primary function lies in enabling machining at precise angular intervals around a fixed point, commonly referred to as indexing. This capability facilitates the creation of intricate geometries, circular features, and multi-sided machining without the need for manual repositioning of the workpiece. A clamp kit for a rotary table is used to secure workpieces onto the rotary table during machining operations. Rotary tables are often used in machining setups to enable circular cutting, hole drilling, and other operations around a fixed axis of rotation. Table Diameter: 4 inches (100 mm)This size is ideal for handling small to medium-sized workpieces, offering a good balance between compactness and functionality. 360-Degree Graduation:The table is graduated a full 360 degrees, allowing for precise control and positioning of the workpiece. The clear markings ensure easy and accurate angle setting for all your milling tasks. Worm Gear Ratio: 1:36The gear ratio means that one full rotation of the handle turns the table by 10 degrees, providing fine control over the movement and ensuring precision in every operation. Vertical Position Center Height: 2-1/16" (50 mm approx)The center height in the vertical position is 2-1/16 inches, which aligns perfectly with the smaller milling machine setups, offering versatility in workpiece positioning. Handwheel Graduations:The handwheel is graduated in divisions of 10 minutes, allowing for highly detailed adjustments. The scale can also be set to zero, making it easy to track and repeat your adjustments for consistent results. Mounting Flexibility:The Regular model can be mounted in both horizontal and vertical positions, enhancing its versatility for a wide range of applications. Whether you need flat or angled cuts, this rotary table can handle it with ease. M6 Clamp Kit This M6 clamp kit is designed for use with 3" or 4" rotary tables. Includes a set of clamps, bolts, nuts, and T-slot nuts. Compatible with rotary tables featuring M6 T-slots or mounting holes. Allows for secure fastening of workpieces onto the rotary table during machining operations. Made of tool steel for durability and reliability. Provides essential holding power to maintain precision and accuracy. Ideal for use in machining setups requiring precise rotary table positioning.

$103.50 - $130.00

-

4"/ 100 mm Regular Rotary Milling Indexing Table With Small Chucks and back Plate

Use of product- A rotary table is used to rotate a workpiece precisely during machining, allowing for accurate creation of circular features, angles, and indexing tasks. A chuck is used to securely hold and grip a workpiece on a machine tool, ensuring it remains stable and aligned during operations like turning, drilling, or milling. 4"/ 100 mm Rotary Table Very High Quality 4" /100 mm Regular Rotary Table designed for smaller milling machines Table is graduated 360 Degrees. Worm Gear Ratio -1:36, which means that the 1 handle rotation shall turn the table by 10 Degrees. Center Height in vertical position: 2-1/16" (50 mm approx) Hand wheel is graduated in divisions of 10 min & can be set to zero. Can be mounted both in Horizontal & vertical position. Chuck 65 mm 3 Jaw Self Centering Precision 65mm 3-Jaw Self-Centering Lathe Chuck Compatible with M14 x 1 mm threading Chuck 65 mm 4 Jaw Self Centering Precision 65mm 4-Jaw Self-Centering Lathe Chuck Compatible with M14 x 1 mm threading Chuck 70 mm 4 Jaw Independent Precision 70 mm 4-Jaw Independent Lathe Chuck Compatible with M14 x 1 mm threading M6 Clamp Kit Versatile M6 clamp kit designed specifically for use with 3" and 4" Rotary Tables. Compatible with both Horizontal and Tilting models of the specified Rotary Tables. Comprehensive set includes 2 step blocks, 2 tee bolts with flanged nuts, and 2 clamps. Each bolt features a length of 55 mm overall and is threaded with M6 for easy installation. Ensures secure and stable positioning for precise machining operations. Crafted with quality materials for durability and long-lasting performance. Streamlines workflow by facilitating effortless adjustment and fastening. Ideal for professional machinists and hobbyists seeking reliable tooling solutions.

$149.99 - $159.99

-

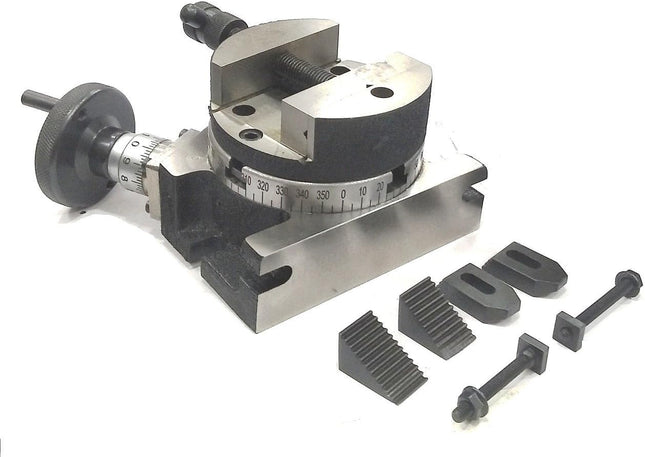

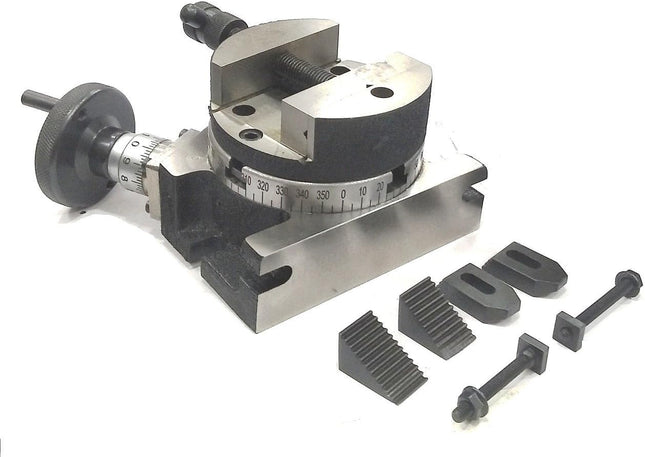

Rotary Table With 70 mm 4 Jaw Independent Chuck and back Plate

A rotary table is used to rotate a workpiece precisely during machining, allowing for accurate creation of circular features, angles, and indexing tasks. A chuck is used to securely hold and grip a workpiece on a machine tool, ensuring it remains stable and aligned during operations like turning, drilling, or milling. Chuck 70 mm 4 Jaw Independent Precision 70 mm 4-Jaw Independent Lathe Chuck Compatible with M14 x 1 mm threading 3"/ 80 mm Rotary Table Small low profile Rotary Table for Milling operation with Table Diameter - 3 Inches (80 mm) Vertical Height - 1-5/8 Inch Gear Ratio - 36:1, which basically means that the 1 rotation of the handle shall rotate the table by 10 degrees. Base Dimensions: 4. 1/8" x 3. 1/4" 4 T-Slots: 5/16" Table scale is calibrated in 5 degree increment. Can be used both in horizontal & vertical position. 3"/ 80 mm tilting Table Low Profile Precision Mini Rotary Table 3" 75mm is manufactured from Seasoned casting. Worm- Gear Ratio - 36:1, which basically means that the 1 rotation of the handle shall rotate the table by 10 degrees. Can be used both in horizontal & vertical position. Weight-3 Kg Material :- Tool Steel & Casting 4"/ 100 mm Regular Table Very High Quality 4" /100 mm Regular Rotary Table designed for smaller milling machines Table is graduated 360 Degrees. Worm Gear Ratio -1:36, which means that the 1 handle rotation shall turn the table by 10 Degrees. Center Height in vertical position: 2-1/16" (50 mm approx) Hand wheel is graduated in divisions of 10 min & can be set to zero. Can be mounted both in Horizontal & vertical position. 4"/ 100 mm tilting Table Horizontal & Vertical Rotary Table 4" Table height 66 mm in flat position Table graduated 360 degrees in 5 degree divisions. Rotary Tables deliver precise, continuous rotating motion for scanning, assembly, testing and production. They are a convenient, accurate method of quickly positioning a payload. The tables use a rugged worm and gear drive design with a central rotating ball bearing.

$98.99 - $153.00

-

HSS M2 Grade Woodruff Hardened Keyseat Cutter - Set of 10 Pcs, 1/2" Shank Diameter, Straight Tooth Cutters

A Woodruff cutter, also known as a Woodruff keyseat cutter, is a specialized tool used in machining to create Woodruff keyseats, which are semicircular slots cut into a shaft. These keyseats are designed to hold Woodruff keys, which are small, semicircular metal pieces used to lock gears, pulleys, or other machine components onto a rotating shaft. Upgrade your machining capabilities with our premium HSS M2 Grade Woodruff Hardened Keyseat Cutter Set. This set includes 10 precision-engineered straight tooth cutters, designed for creating accurate grooves or slots to accommodate engagement keys. These cutters are essential for key shaft applications, ensuring secure and precise fits to prevent unwanted rotation or movement. Key Features: High-Quality Material: Crafted from HSS M2 grade steel, these cutters offer superior hardness and durability, ensuring long-lasting performance even in demanding conditions. Comprehensive Set: This set includes 10 pieces with varying dimensions to suit a wide range of applications. Shank Diameter: 1/2" shank diameter, compatible with standard milling machines. Straight Tooth Design: Provides clean and precise cuts, making it ideal for producing keyseats with consistent accuracy. Cutter Dimensions (Dia x Thickness): STD 403: 3/8" x 1/2" STD 204: 1/2" x 1/16" STD 404: 1/2" x 1/8" STD 305: 5/8" x 3/32" STD 505: 5/8" x 5/32" STD 406: 3/4" x 1/8" STD 606: 3/4" x 3/16" STD 806: 3/4" x 1/4" STD 608: 1" x 3/16" STD 808: 1" x 1/4" Application: Ideal for machining keyseats in various materials, these cutters are indispensable for mechanical engineers and machinists working on key shafts, offering reliable performance for precise keyseat creation. Why Choose Our Woodruff Cutter Set? Our Woodruff cutters are meticulously crafted to meet industrial standards, ensuring you get the best tool for your machining needs. Whether you're a professional machinist or an industrial buyer, this set provides the versatility and durability required for a wide range of projects. Order Now: Enhance your machining toolkit with this comprehensive Woodruff cutter set and achieve precise, reliable results every time.

$69.99 $62.90

-

Milling Indexing 4"/100 mm Rotary Table Horizontal Vertical with Suitable Round Vices & Clamp Kits

A rotary table is a precision tool used predominantly in metalworking, particularly in machining operations like milling and drilling. Its primary function lies in enabling machining at precise angular intervals around a fixed point, commonly referred to as indexing. This capability facilitates the creation of intricate geometries, circular features, and multi-sided machining without the need for manual repositioning of the workpiece. By mounting the workpiece on the rotary table and rotating it, machinists can execute complex operations such as gear cutting, spiral grooving, and helical cuts with high precision. Additionally, rotary tables are essential for tasks requiring circular or arc-shaped machining, offering versatility and efficiency in manufacturing processes. 4"// 100 mm Rotary Table Dual functionality: Can be used horizontally or vertically to accommodate a wide range of machining tasks. Generous 4" inch (100 mm) diameter provides ample space for various workpieces. Smooth rotary motion ensures precise positioning and milling operations. Sturdy construction for durability and long-lasting performance. Compatible with both horizontal and vertical milling machines, enhancing flexibility in your workshop. Precision-machined for exceptional accuracy, delivering reliable results with every use. 3"// 80 Round vice Made of high grade close grain caste Iron. Fits our 3" (75 mm) Rotary Tables perfectly. These vices are drilled in a manner that these can fit to a 3 as well 4 slot table. Diameter of Base : 80 mm Jaw Width : 54 mm Jaw Depth: 20 mm Jaw Opening : 32 mm Height : 29 mm 4"// 100 mm Round vice Made of high grade close grain caste Iron. Fits our 3" (75 mm) Rotary Tables perfectly. These vices are drilled in a manner that these can fit to a 3 as well 4 slot table. Diameter of Base : 100 mm Jaw Width : 79 mm Jaw Depth: 20.5 mm Jaw Opening : 40 mm Height : 33 mm

$122.00 - $159.99