CNC Metalworking & Manufacturing

-

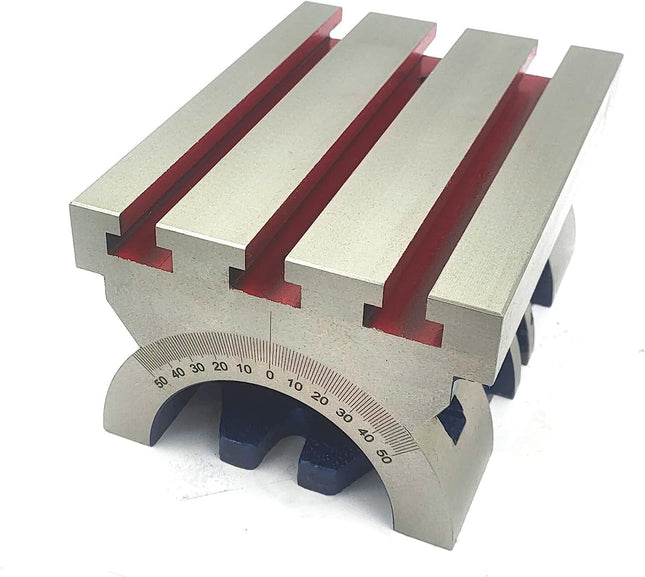

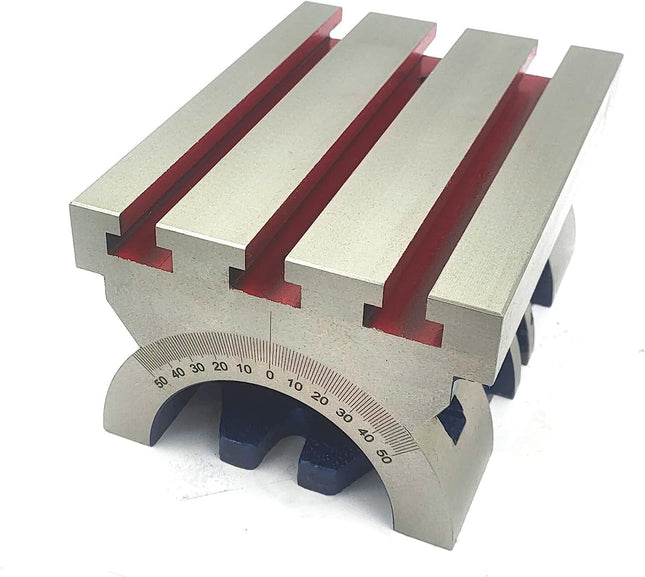

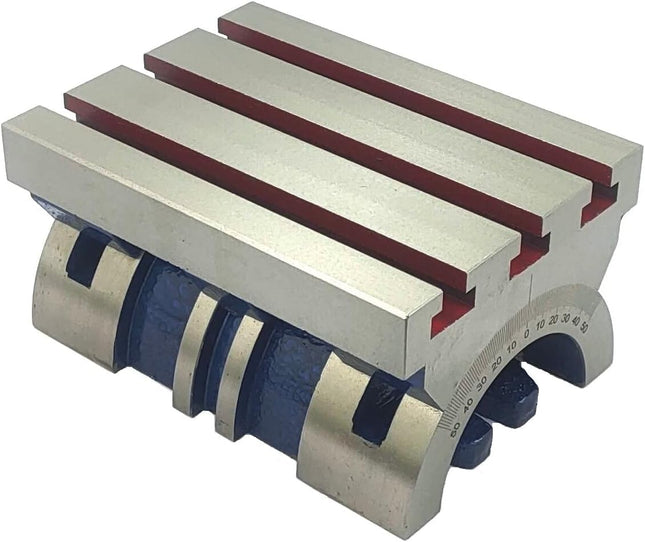

Tilting Table for Milling Machine

High-Precision Tilting Table for Milling Machines Use of product- A tilting table for a milling machine is an accessory that provides angular positioning for workpieces. It is used to tilt the workpiece to a specific angle, allowing for machining operations that require angled cuts, such as beveling, chamfering, and creating complex geometric shapes. Enhance your machining capabilities with our High-Precision Tilting Table, designed to deliver superior accuracy and versatility for your milling operations. Key Features: Adjustable Angle Range: Achieve precise angular positioning with a tilting range of 0° to 45°, perfect for beveling, chamfering, and complex angle cuts. Precision Scale: Features a clearly marked scale and adjustable stops for easy and accurate angle settings, ensuring repeatable precision. Sturdy Construction: Built from high-quality cast iron, this tilting table provides exceptional durability and stability, reducing vibrations and enhancing machining accuracy. Smooth Operation: Equipped with precision-ground ways and a high-quality lead screw for smooth and effortless angle adjustments. Versatile Mounting: Compatible with most milling machines, the tilting table includes multiple mounting slots for secure and flexible attachment of workpieces. Enhanced Productivity: Reduces the need for multiple setups, saving time and increasing efficiency in your machining processes. Applications: Ideal for creating angled cuts and complex geometric shapes. Perfect for precision engineering tasks in aerospace, automotive, and metalworking industries. Suitable for both professional workshops and hobbyist machinists seeking to expand their capabilities. Specifications: Material: High-quality tool steel Tilting Range: 45- 0-45 Degrees Table Size: 4" X 5" Inches/ 100 X 125 mm & 5" X 7" Inch / 125 X 175 mm For 4" x 5" Height in Horizontal Position 80 mm and for 5" x 7" is 90 mm Neatly Machined T Slots. Why Choose Our Tilting Table? Unmatched Precision: Ensure every cut is exact with our meticulously designed scale and adjustment mechanism. Robust Build: Count on a tilting table that withstands the rigors of daily use while maintaining top performance. Ease of Use: Simple adjustments and a user-friendly design make it easy to integrate into any milling setup. Upgrade your milling machine today with our High-Precision Tilting Table and experience a new level of accuracy and efficiency in your machining projects. Order now and take your craftsmanship to the next level!

$89.90 - $107.90

-

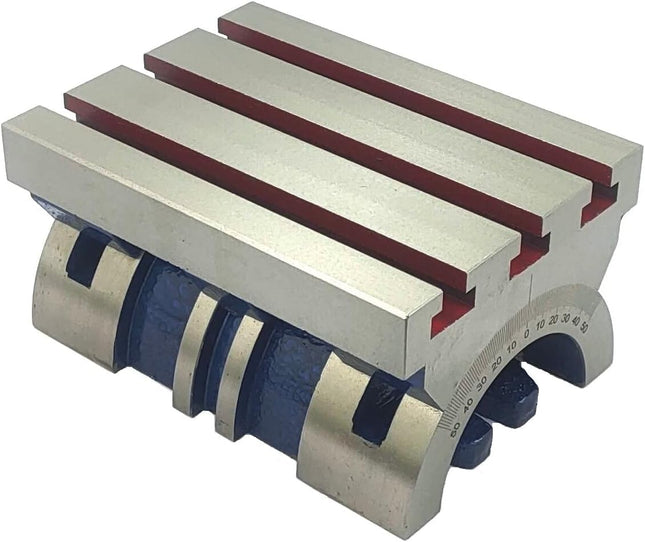

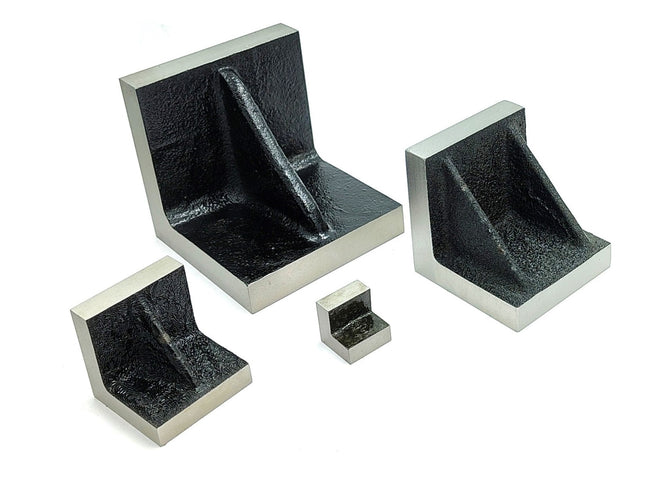

Stress Relieved Caste Iron Solid Webbed Angle Plate

An angle plate is a precision tool used in metalworking and machining. It is a flat plate that is precision ground to have a 90-degree angle between two of its surfaces. Angle Plate - Precision Machined for Metalworking and Inspection Available Sizes: 1" x 1" x 1" 2" x 2" x 2" 3" x 3" x 3" 4" x 4" x 4" Wall Thickness: 1/2" Structure: Solid Webbed Description: Enhance the accuracy and efficiency of your machining and inspection processes with our precision-machined angle plates. Crafted from high-quality materials, these angle plates are designed to provide reliable performance in various industrial applications. Features: Precision Machining: Each angle plate is machined to exacting standards, ensuring accurate 90-degree angles between surfaces for precise positioning and measurement. Solid Webbed Structure: The robust webbed design enhances strength and stability, making these angle plates suitable for heavy-duty use. Uniform Wall Thickness: With a consistent wall thickness of 1/2", these plates offer durability and resistance to deformation under load. Versatile Sizes: Available in four convenient sizes, our angle plates can accommodate a wide range of workpiece dimensions and machining requirements. Applications: Workpiece Positioning: Ideal for holding workpieces in precise positions during machining operations such as milling, drilling, and grinding. Inspection: Use as a reference surface for inspecting parts and ensuring they meet specified tolerances. Assembly: Perfect for assembling jigs, fixtures, and other setups requiring accurate angles and alignments. Work Holding: Securely hold workpieces in vertical or horizontal positions on machine tables or in vises. Benefits: Improved Accuracy: Achieve consistent and accurate results in your machining and inspection tasks. Enhanced Stability: The solid webbed structure provides added strength and stability, reducing the risk of movement or misalignment. Versatile Use: Suitable for a wide range of applications in metalworking and manufacturing environments. Upgrade your workshop with our high-quality angle plates and experience the difference in precision and reliability. Whether you're a professional machinist or a DIY enthusiast, these angle plates are an essential tool for achieving superior results in your projects.

$17.90 - $44.50

-

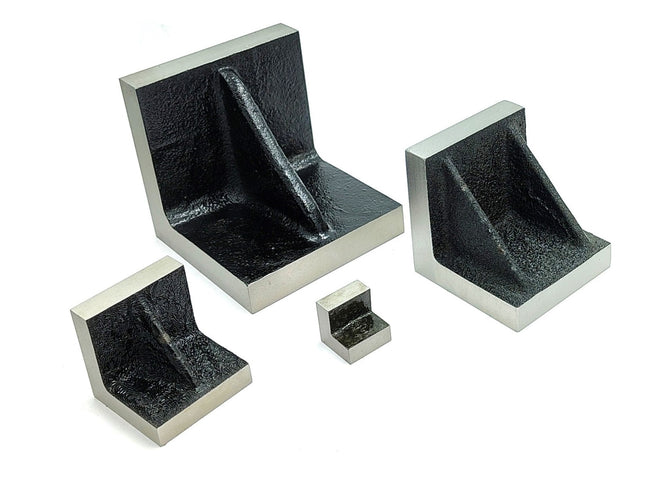

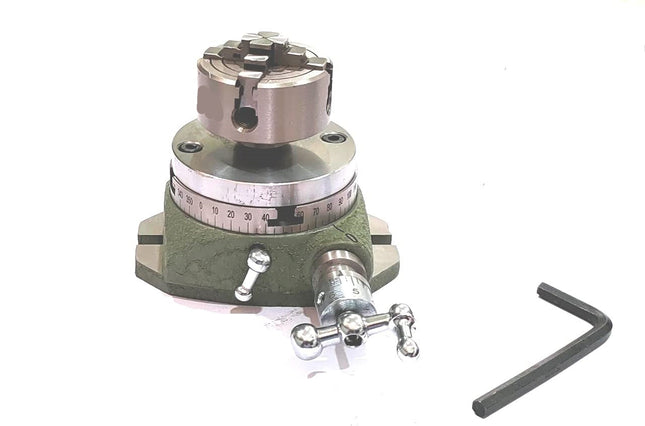

Small Watchmaker 2-3/4" (2.75 Inch) Rotary Table with 50 mm Chuck and Back Plate

The small watchmaker rotary table is a versatile tool with a multitude of uses. It's indispensable in precision watchmaking, enabling accurate drilling, milling, and engraving for crafting and repairing intricate watch components. Additionally, it's favored by jewelry makers for its ability to shape metals with precision, from setting stones to creating bespoke jewelry pieces. Small Watchmaker 2-3/4" (2.75 Inch) Rotary Table The small watchmaker rotary table is a versatile tool with a multitude of uses. It's indispensable in precision watchmaking, enabling accurate drilling, milling, and engraving for crafting and repairing intricate watch components. Additionally, it's favored by jewelry makers for its ability to shape metals with precision, from setting stones to creating bespoke jewelry pieces. Compact Design: Table Diameter of 2.75 inches (72 mm) and a height of 1.5 inches (39 mm) when laid horizontally, offering a space-efficient solution. Precision Performance: Worm-Gear Ratio of 1:48 ensures precise positioning, with each handle rotation turning the table by 7.5 degrees, ideal for intricate milling tasks. Versatile Utility: Preferred choice among Watchmakers, Jewelry Tools, Model Makers & Hobbyists for its versatility in engraving, drilling, cutting, and shaping small components. Robust Construction: Crafted with high-quality materials and precision machining, guaranteeing durability and reliability for professional workshops and hobbyist setups. Smooth Operation: Equipped with smooth ball bearings and precision gearing, enabling effortless rotation and stable operation for flawless milling results. User-Friendly: Designed with ergonomic handles and intuitive controls for ease of use, reducing operator fatigue during extended milling sessions. Trusted Performance: Trusted by professionals and hobbyists alike for consistent precision and reliability, meeting exacting standards for precision milling applications. Available in 2 slots and 4 slots 50 mm Chuck -3 Jaw Self Centering (M12 x 1) Caste Iron Body 50 mm 3 Jaws Self Chucks with Tool Steel Hardened Jaws Body Diameter 50 mm , Mounting thread M12 x 1 It can hold any long round bar up to 12 mm, which can pass through the chuck's bore. 50 mm Chuck -4 Jaw Self Centering (M12 x 1) Caste Iron Body 50 mm 3 Jaws Self Chucks with Tool Steel Hardened Jaws Body Diameter 50 mm , Mounting thread M12 x 1 It can hold any long round bar up to 12 mm, which can pass through the chuck's bore. 50 mm Chuck - 4 Independent (M12 x 1) Caste Iron Body 50 mm 4 jaw Independent Dog Chucks with Hardened Tool Steel Jaws Graded Caste Iron Body and Hardened Tool Steel Jaws Mounting thread M14 x 1, same as that of the Arbors. Jaws are Hardened & Precisely Ground. Great for Holding Small Jobs upto 12 mm diameter both for Metal or Wood Working

$110.00 $99.00

-

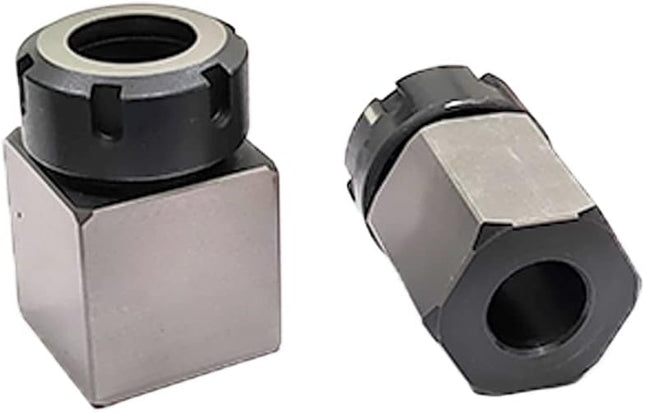

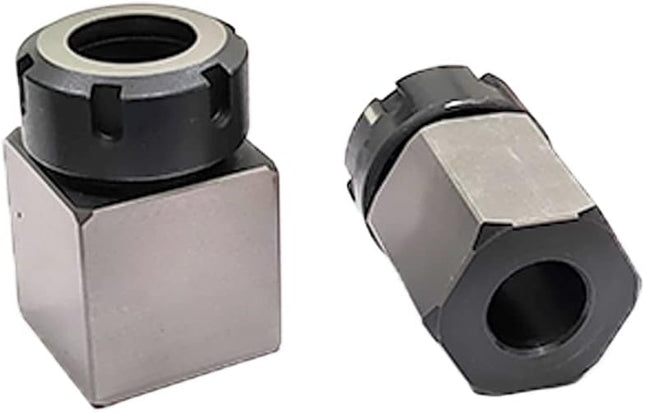

Precision ID ground blue matched ER-32 collet chuck block adapter for CNC Lathe

A collet chuck block adapter is used to enable a CNC machine spindle to securely hold and accurately center tools of different sizes using interchangeable collets, thus enhancing machining versatility, efficiency, and precision. Features: High Precision ID Ground: The internal diameter is precisely ground to ensure exceptional accuracy and a tight fit for ER-32 collets. Blue Matched Finish: The collet chuck block features a durable blue finish, providing corrosion resistance and an aesthetically pleasing appearance. Versatile Compatibility: Compatible with ER-32 collets, making it suitable for a wide range of machining applications. Robust Construction: Made from high-quality alloy steel for superior strength and longevity. Ease of Use: Designed for quick and easy installation on CNC lathes, improving workflow efficiency. Enhanced Performance: Provides stable and reliable holding power, ensuring consistent machining results. Applications: CNC Lathe Operations Milling Machines Drilling and Tapping Precision Machining Tool and Die Making Specifications: Type: ER-32 Collet Chuck Block Adapter Material: Alloy Steel Finish: Blue Matched Internal Diameter: Precision Ground Compatibility: ER-32 Collets Comes in: Hex Shape, Square Shape Benefits: High Precision: Ensures accurate and consistent machining operations. Durable Finish: Blue matched finish offers protection against corrosion and wear. Versatility: Suitable for a wide range of CNC lathe and machining applications. Time-Saving: Quick and easy to install, reducing setup time and increasing productivity. Reliable Performance: Provides stable holding power for consistent machining results. Why Choose Our ER-32 Collet Chuck Block Adapter? Unmatched Precision: Our collet chuck block adapter is precision-engineered to meet the highest standards of accuracy, ensuring reliable performance in every use. Durability: Constructed from high-quality materials and finished with a blue matched coating, this adapter is built to withstand the rigors of heavy-duty machining. Versatile Use: Whether you’re working on a CNC lathe, milling machine, or other precision machining equipment, this adapter is designed to deliver exceptional results. Upgrade your CNC lathe operations with our Precision ID Ground Blue Matched ER-32 Collet Chuck Block Adapter and experience the difference in performance and precision.

$39.99 - $69.99

-

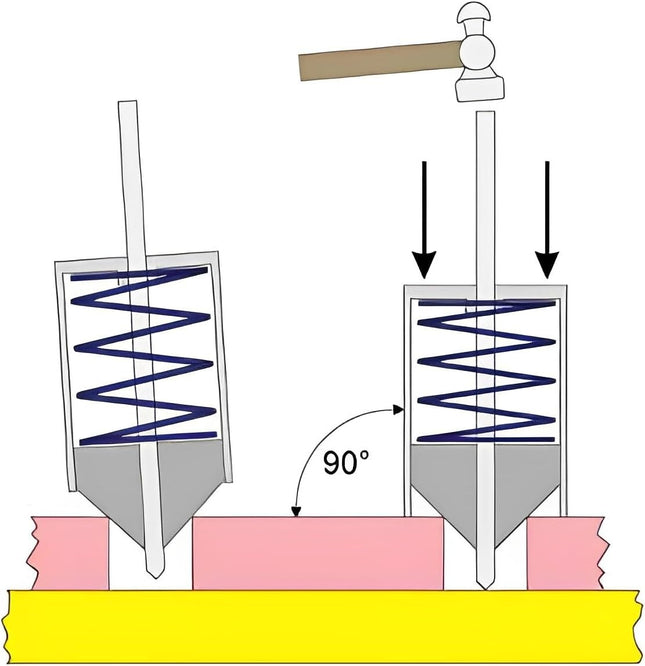

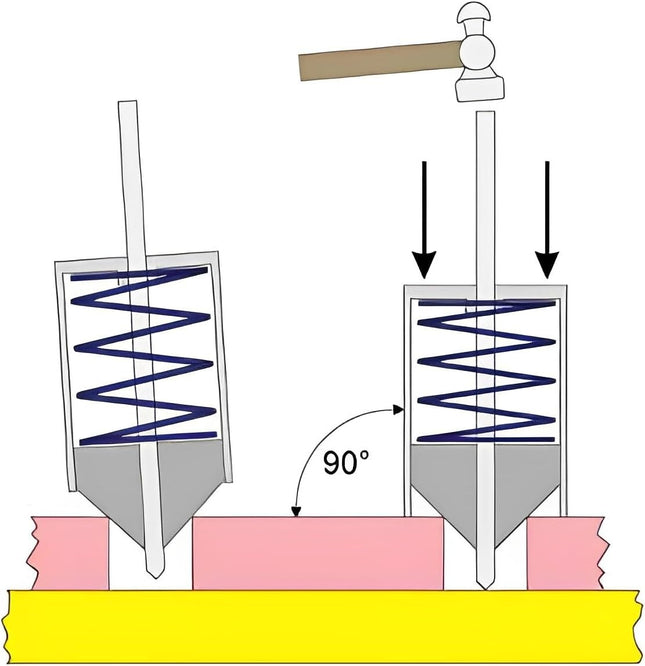

Buyohlic Universal Transfer Punch Center Aligner Punch Machine Tools

Universal transfer punches are precision tools used in metalworking and machining to transfer the precise location of holes or features from one workpiece to another. They ensure accuracy in drilling and machining processes by creating marks or indentations that guide the placement of subsequent operations, ensuring alignment and consistency across multiple parts or components. Features: Wide Range of Sizes: Covers hole sizes from 1/4" to 1", replacing the need for different-sized regular transfer punches. Knurled Body: Provides a better grip, ensuring control and stability during use. Automatic Alignment: Automatically accommodates itself to transfer center holes accurately, reducing the risk of errors. CNC Made: Precision-engineered for accuracy and durability. Hardened Guide Cone: Ensures precise placement into the clean edge of the hole to be transferred. Oversized Pin Head: Prevents the pin from slipping out through the body, ensuring reliable performance. Sliding Centre Punch: Can be struck to mark the workpiece with precision. Applications: Metalworking Woodworking Fabrication Machining DIY Projects Specifications: Material: Alloy Steel Small Sizes: 1/4" to 5/8" Big Sizes: 3/8" to 1" Body: Knurled for better grip Guide Cone: Hardened for precise placement Pin Head: Oversized to prevent slipping Benefits: Replaces multiple regular transfer punches, saving space and cost Ensures accurate transfer of center holes Reduces setup time and improves precision Minimizes errors and rework Usage Instructions: Insert the hardened guide cone into the clean edge of the hole to be transferred. Use the sliding center punch to mark the workpiece accurately. The oversized pin head ensures the punch remains securely in place during operation.

$17.99 - $39.99

-

Buyohlic Universal Transfer Punch Center Aligner Punch Machine Tools- Old Style

Universal transfer punches are precision tools used in metalworking and machining to transfer the precise location of holes or features from one workpiece to another. They ensure accuracy in drilling and machining processes by creating marks or indentations that guide the placement of subsequent operations, ensuring alignment and consistency across multiple parts or components. Features: Wide Range of Sizes: Covers hole sizes from 1/4" to 1", replacing the need for different-sized regular transfer punches. Knurled Body: Provides a better grip, ensuring control and stability during use. Automatic Alignment: Automatically accommodates itself to transfer center holes accurately, reducing the risk of errors. CNC Made: Precision-engineered for accuracy and durability. Hardened Guide Cone: Ensures precise placement into the clean edge of the hole to be transferred. Oversized Pin Head: Prevents the pin from slipping out through the body, ensuring reliable performance. Sliding Centre Punch: Can be struck to mark the workpiece with precision. Applications: Metalworking Woodworking Fabrication Machining DIY Projects Specifications: Material: Alloy Steel Small Sizes: 1/4" to 5/8" Big Sizes: 3/8" to 1" Body: Knurled for better grip Guide Cone: Hardened for precise placement Pin Head: Oversized to prevent slipping Benefits: Replaces multiple regular transfer punches, saving space and cost Ensures accurate transfer of center holes Reduces setup time and improves precision Minimizes errors and rework Usage Instructions: Insert the hardened guide cone into the clean edge of the hole to be transferred. Use the sliding center punch to mark the workpiece accurately. The oversized pin head ensures the punch remains securely in place during operation.

$20.90 - $44.50

-

ER Collet Adaptors For Rotary Milling Tables With Fixing T Nuts

ER collet adapters are used to expand the range of tool sizes that can be held by a machine tool or spindle that uses ER collets. By using ER collet adapters, machinists can utilize a wider range of cutting tools without needing separate dedicated tool holders for each collet size, thereby optimizing tooling flexibility, reducing costs, and streamlining setup and changeover times in manufacturing processes. Introduction: ER collet adaptors are precision tool holders used to secure cutting tools in rotary milling tables. They provide a robust and versatile solution for various machining tasks, ensuring high accuracy and repeatability. Design and Construction: Made from high-quality, hardened steel for durability and long-lasting performance. Precision ground to ensure a perfect fit and maximum concentricity. Available in various sizes to accommodate different tool shanks. Compatibility: Designed to fit standard rotary milling tables. Compatible with a wide range of ER collet sizes (e.g., ER11, ER16, ER20) Suitable for use with CNC machines, lathes, and manual milling machines. Clamping Range: ER collets offer a wide clamping range, typically from 1mm to 34mm, depending on the collet size. Provides a secure grip on the tool, minimizing vibration and runout during machining. Advantages: High precision: Ensures accurate tool positioning and stable machining operations. Versatility: Can hold various types of tools, including end mills, drill bits, and taps. Ease of use: Simple to install and change tools quickly, reducing downtime. Improved productivity: Enhances machining efficiency by maintaining tool stability and reducing tool wear. By following these points, users can understand the key features and benefits of ER collet adaptors for rotary milling tables, ensuring they select the right adaptor for their specific machining needs.

$35.50 $32.50

-

Steel Dividing Indexing Plates for Rotary Tables

How it's works: When mounted onto a rotary table, which is a precision workholding device that allows for precise positioning of workpieces, the dividing plate helps in accurately dividing the rotation of the table into equal parts. This division is crucial for tasks like cutting gears, splines, or other components that require precise angular spacing or indexing. Premium Quality Construction: Constructed from high-grade tool steel, ensuring durability and longevity for extended usage. Precision Indexing: Engineered for precise division and indexing, allowing for accurate positioning of workpieces during machining operations. Smooth Rotation: Facilitates smooth rotation on rotary tables, enabling seamless transitions between indexing positions. Versatile Compatibility: Compatible with a wide range of rotary tables, ensuring versatility and adaptability for various machining setups. Enhanced Machining Accuracy: Enables users to achieve fine increments and accurate divisions, enhancing overall machining precision. Easy Installation: Designed for hassle-free installation, allowing users to quickly integrate the indexing plates into their rotary table setups. Reliable Performance: Offers reliable performance under demanding machining conditions, ensuring consistent results with each use. Professional Grade: Ideal for both professional machinists and hobbyists alike, providing professional-grade quality for diverse machining projects. Tools Specification: Dividing Plates Set for HV4 /HV6 Rotary Table: Set Includes: 3 x Indexing Dividing Plate and accessories. Diameter of the Plates is 100 mm. Centre Hole of the Plate is 21 mm. Thickness 7 mm Plate 1 – 15, 16, 17, 18, 19, 20 Plate 2 – 21, 23, 27, 29, 31, 33 Plate 3 – 37, 39, 41, 43, 47, 49 Dividing Plates Set for HV8 /HV10/ HV12/ HV14 Rotary Table: Set Includes: 2 x Indexing Dividing Plate and accessories. Diameter of the plate is 7" and its thickness is 0.47 " Inches (12 mm) approx. All required accessories are included as photograph. No manual is included, please note. Plate A - 28, 32, 37, 39, 43, 46, 49, 53, 59 Plate B - 63, 69, 73, 79, 83, 89, 93, 99 {Internal reference: HM}

$45.50 - $129.99

-

Heavy Duty Chucks for HV4 I 5 I 6 Rotary Tables and Lathe Machines

Purpose: The chuck for a rotary table typically has jaws or clamps that can be adjusted to securely grip the workpiece. It ensures that the workpiece remains stable and properly aligned during the machining process, allowing for accurate and consistent results. This is especially important for tasks that require precise positioning or multiple machining operations on different sides of the workpiece. Versatile Chuck Set: Upgrade your rotary table or mini lathe with this set of small chucks designed to fit HV4 I 5 I 6 Rotary Tables and Lathe machines, enhancing their functionality and versatility. Precision Engineering: Crafted with precision to ensure optimal performance, these chucks provide secure grip and smooth rotation, essential for accurate machining and turning operations. Durable Construction: Made from high-quality caste iron, these chucks are built to withstand the rigors of machining tasks, ensuring long-lasting durability and reliability. Easy Installation: Simple to install and compatible with most rotary tables and mini lathes, these chucks allow for quick setup and seamless integration into your workshop or machining setup. Wide Application: Ideal for a variety of machining projects, these chucks enable you to securely hold workpieces of different shapes and sizes, expanding the capabilities of your rotary table or mini lathe. Compact Design: With their small size, these chucks are perfect for use with compact machinery, allowing you to maximize space efficiency in your workshop without sacrificing performance. Enhanced Efficiency: By providing a secure and stable grip on workpieces, these chucks help improve machining accuracy and efficiency, allowing you to achieve professional results with ease. Professional Results: Whether you're a hobbyist or a professional machinist, these small chucks are essential tools for achieving precision and accuracy in your machining and turning projects. {Internal Refence: HM}

$80.99 - $122.50

-

80 mm Chucks for 3" I 80 mm & 4" Inch I 100 mm Rotary Tables & Small Bench Top Lathe Machines

Purpose: The chuck for a rotary table typically has jaws or clamps that can be adjusted to securely grip the workpiece. It ensures that the workpiece remains stable and properly aligned during the machining process, allowing for accurate and consistent results. This is especially important for tasks that require precise positioning or multiple machining operations on different sides of the workpiece. Versatile Chuck Set: Upgrade your rotary table or mini lathe with this set of small chucks designed to fit 3" (80 mm) and 4" (100 mm) machines, enhancing their functionality and versatility. Precision Engineering: Crafted with precision to ensure optimal performance, these chucks provide secure grip and smooth rotation, essential for accurate machining and turning operations. Durable Construction: Made from high-quality materials, these chucks are built to withstand the rigors of machining tasks, ensuring long-lasting durability and reliability. Easy Installation: Simple to install and compatible with most rotary tables and mini lathes, these chucks allow for quick setup and seamless integration into your workshop or machining setup. Wide Application: Ideal for a variety of machining projects, these chucks enable you to securely hold workpieces of different shapes and sizes, expanding the capabilities of your rotary table or mini lathe. Compact Design: With their small size, these chucks are perfect for use with compact machinery, allowing you to maximize space efficiency in your workshop without sacrificing performance. Enhanced Efficiency: By providing a secure and stable grip on workpieces, these chucks help improve machining accuracy and efficiency, allowing you to achieve professional results with ease. Professional Results: Whether you're a hobbyist or a professional machinist, these small chucks are essential tools for achieving precision and accuracy in your machining and turning projects. ( 80 mm 4 Jaws Independent Dog chuck with Back Plate ) The Back plate has been counter drilled to fit to our 3"/ 80mm & 4"/ 100 mm Rotary tables. The other side of the Back plate has a small spigot to fit /adjust into the center of the Rotary table for better accuracy and Fitting. Supplied with Fixing T nuts Bolts. ( 80 mm 3 Jaws Self Centering chuck ) 3" /80 mm Rotary table. Recess is 55 mm Total Height excluding the jaws (Only Body) : 45 mm. The Back plate is drilled with M6 size tapped holes for the chuck's bolts to be screwed with the back plate and then provided with 2 counter drills to them clamp it with the Rotary table's T slots. The Chuck body is made of high grain casting and the jaws are made of hardened tool steel for a long life. The chuck recess is 55 mm same as that of the back plate. The back plate has a 13.9 mm small spigot that helps it in centrally locate it in the center of the Rotary Table. {Internal Refence: HM}

$79.50 $71.50

-

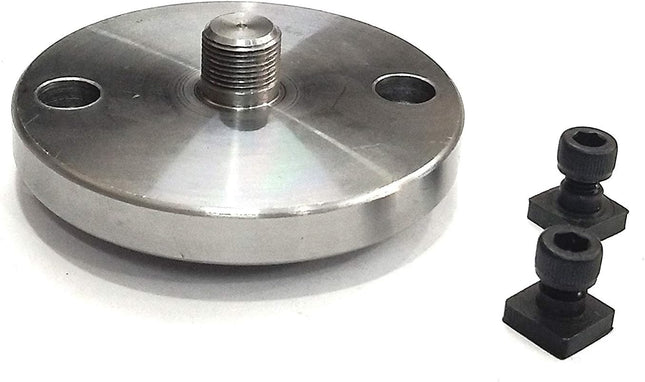

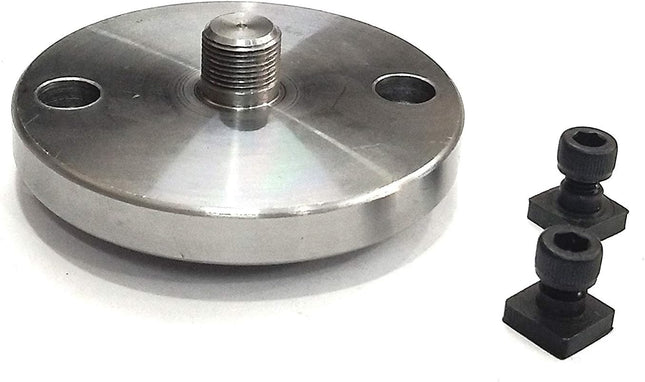

Tool Steel's 65 mm Back Plate for mounting 50 mm Chucks on watchmaker, 2.75" Inch Rotary Tables

Use of product- Back plates serve as mounting surfaces for workpieces or fixtures. They facilitate the secure attachment of the workpiece or fixture to the rotary table, enabling precise machining operations such as milling, drilling, or grinding. Additionally, back plates may incorporate features such as T-slots or mounting holes to accommodate different types of workpieces and tooling setups, enhancing versatility and accuracy in machining processes. Enhance the versatility and functionality of your rotary table with our precision back plate. Crafted from high-quality [Material], this back plate ensures reliable performance and durability for all your machining needs. Features: Robust Construction: Engineered from sturdy tool steel, our back plate is built to withstand heavy-duty machining operations, providing stable support for your workpieces. Precision Machining: Designed with meticulous attention to detail, our back plate offers precise alignment and compatibility with your rotary table, ensuring accurate machining results. Universal Compatibility: Compatible with a wide range of rotary tables, our back plate is a versatile addition to your workshop, catering to various machining projects. Easy Installation: Installing our back plate is quick and straightforward, allowing you to attach it to your rotary table effortlessly for immediate use. Secure Mounting: Equipped with sturdy mounting holes, our back plate ensures a secure and stable connection to your rotary table, minimizing vibrations during machining. Smooth Surface Finish: Finished with a smooth surface, our back plate provides an ideal mounting surface for your workpieces, reducing friction and enhancing machining precision. Size Options: 65 mm diameter back plate in M12 x 1 and M14 x 1 thread. Package Includes: 1 x Precision Back Plate for Rotary Table 3 x Tee Nuts Bolts Upgrade your machining capabilities with our precision back plate for rotary tables. Order now and experience enhanced accuracy and efficiency in your workshop!

$12.95 $11.95

-

Tool Steel 70 mm Back Plates for Mounting Small Chucks on Rotary Tables

Back plates serve as mounting surfaces for workpieces or fixtures. They facilitate the secure attachment of the workpiece or fixture to the rotary table, enabling precise machining operations such as milling, drilling, or grinding. Additionally, back plates may incorporate features such as T-slots or mounting holes to accommodate different types of workpieces and tooling setups, enhancing versatility and accuracy in machining processes. Enhance the versatility and functionality of your rotary table with our precision back plate. Crafted from high-quality [Material], this back plate ensures reliable performance and durability for all your machining needs. Features: Robust Construction: Engineered from sturdy tool steel, our back plate is built to withstand heavy-duty machining operations, providing stable support for your workpieces. Precision Machining: Designed with meticulous attention to detail, our back plate offers precise alignment and compatibility with your rotary table, ensuring accurate machining results. Universal Compatibility: Compatible with a wide range of rotary tables, our back plate is a versatile addition to your workshop, catering to various machining projects. Easy Installation: Installing our back plate is quick and straightforward, allowing you to attach it to your rotary table effortlessly for immediate use. Secure Mounting: Equipped with sturdy mounting holes, our back plate ensures a secure and stable connection to your rotary table, minimizing vibrations during machining. Smooth Surface Finish: Finished with a smooth surface, our back plate provides an ideal mounting surface for your workpieces, reducing friction and enhancing machining precision. Size Options: 70 mm diameter back plate in M12 x 1 and M14 x 1 thread. Package Includes: [1] x Precision Back Plate for Rotary Table [3] x Tee Nuts Bolts Upgrade your machining capabilities with our precision back plate for rotary tables. Order now and experience enhanced accuracy and efficiency in your workshop! {Internal Reference: HM}

$14.50 $12.99