Business & Industrial

-

BUYOHLIC INTERNATIONAL Tap Wrench Holds Taps of Sizes from 3-10 mm (1/8" to 3/8")

A tap wrench is a tool used specifically for hand-tapping threads into a drilled hole in metal, wood, or plastic. It securely holds the tap (a cutting tool used for creating internal threads) and allows the user to rotate it manually to cut threads into the workpiece. Tap wrenches come in various sizes to accommodate different taps and provide leverage for controlled and precise threading operations. Versatile Tap Capacity: Compatible with metric taps from 3 mm to 10 mm. Suitable for a variety of threading tasks in metals, plastics, and other materials. Durable Construction: Made from high-quality, hardened steel for long-lasting durability. Heat-treated for enhanced toughness and resistance to wear and tear. Ergonomic Design: Comfortable, ergonomic handle design provides a secure grip and reduces hand fatigue during prolonged use. Balanced for better control and stability during threading operations. Adjustable Jaw Mechanism: Adjustable jaws allow for quick and secure clamping of taps of various sizes within the 3-10 mm range. Ensures a firm hold, preventing slippage and ensuring accuracy. Precision Engineering: Accurately aligns taps, essential for creating precise and clean threads. Reduces the risk of tap breakage and thread damage, enhancing the quality of the work. Ease of Use: Simple to operate, suitable for both experienced users and beginners. Compact and lightweight design makes it easy to maneuver, even in tight spaces. Versatility: Perfect for use in professional workshops, garages, and home DIY projects. Compatible with various materials including steel, aluminum, brass, and plastic. Low Maintenance: Minimal maintenance required; simple cleaning after use ensures longevity. Resistant to rust and corrosion, maintaining its performance over time.

$12.95 $11.50

-

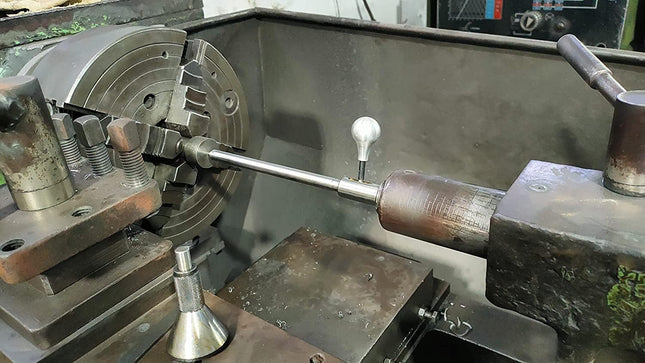

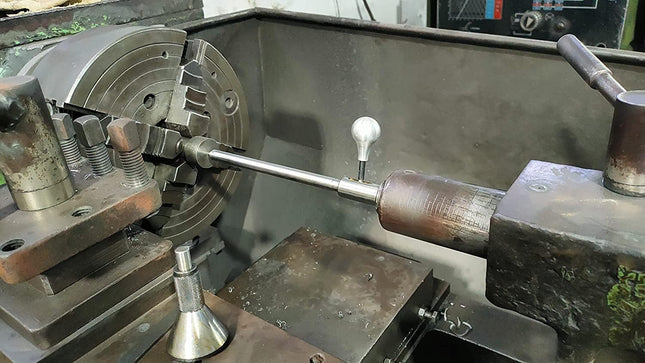

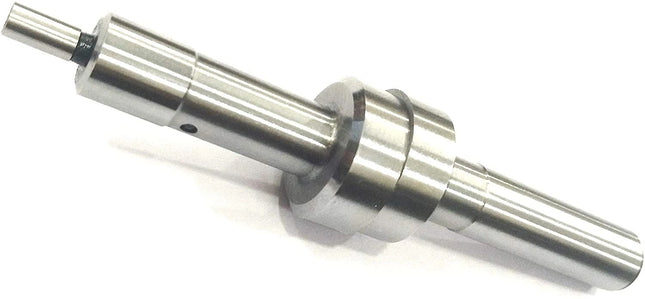

New Centralizer Tool Kit Includes 2MT Shank Centraliser & Engineer Bell Punch For Locating Work-piece Center on Independent Lathe Chuck

Use of Product- Its primary use is to provide a starting point for drilling holes with accuracy and prevent drill bits from slipping off-center. It's widely employed in metalworking, woodworking, jewelry making, and general DIY tasks to ensure precise hole placement for screws, fasteners, or decorative purposes. Key Features: Specifications: 2MT Shank Centralizer: Shank Type: 2 Morse Taper (2MT) Material: Hardened Steel OAL:- 285 mm Length of the needle pin: 185 mm Engineer Bell Punch: Max Diameter (Smaller Size): 35 mm Material: tool steel Precision Engineering: Ensures accurate center finding, crucial for subsequent machining processes. Reduces errors and enhances the quality of finished work by ensuring precise alignment. Versatility: Suitable for a wide range of applications in workshops, fabrication shops, and home DIY projects. Compatible with various types of round bars, including steel, aluminum, brass, and other metals. Ease of Use: User-friendly design makes it accessible even for those with limited experience in metalworking. Quick setup and operation save time and increase productivity. Benefits: Enhanced Productivity: Speeds up the center finding process, allowing for quicker project completion. Improved Accuracy: Ensures consistent and precise center finding, leading to better quality workpieces. Cost-Effective: Reduces material wastage by minimizing errors, saving both time and resources.

$49.95 $45.50

-

Engineer Machinist Bell Punch Hand DIY Tool for Center Finding on a Round Bar Machine Tools

Bell Punch primary use is to provide a starting point for drilling holes with accuracy and prevent drill bits from slipping off-center. It's widely employed in metalworking, woodworking, jewelry making, and general DIY tasks to ensure precise hole placement for screws, fasteners, or decorative purposes. Purpose: Designed specifically for precision center punching on round bars, ensuring accurate and consistent marking. Application: Ideal for machinists, engineers, DIY enthusiasts, and metalworkers who require precise center punching on cylindrical objects. Key Features: Dual Size Options: Smaller Size: Capable of center punching round bars up to 35 mm in diameter. Perfect for smaller projects and fine work requiring high accuracy. Larger Size: Suitable for center punching round bars up to 52 mm in diameter. Ideal for larger bars and heavier duty applications. Material and Build: Constructed from high-quality, durable materials to withstand repeated use and provide long-lasting performance. Engineered for robustness and reliability, ensuring consistent results over time. Design and Usability: Ergonomic hand tool design allows for comfortable and controlled use. Easy to operate, even for those with limited experience in metalworking. Compact and lightweight, making it convenient to carry and use in various settings. Precision Engineering: Provides accurate center finding, crucial for subsequent machining processes. Reduces errors and enhances the quality of finished work by ensuring precise alignment. Versatility: Suitable for a wide range of applications in workshops, fabrication shops, and home DIY projects. Compatible with various types of round bars, including steel, aluminum, brass, and other metals.

$17.00 - $42.50

-

BUYOHLIC INTERNATIONAL Set of 5 Pcs Long & 8 Pcs Short Drive Bolt Catch Roll Pin Punch Set-Hard & Ground/Imperial Assembly Kit

Use of product- A pin punch is a tool used for driving out or removing pins, bolts, or rivets from mechanical assemblies. It typically has a long, slender, cylindrical shape with a pointed end that fits into the pin or rivet head. By striking the opposite end of the pin punch with a hammer or mallet, it applies force to the pin, allowing it to be pushed out of its hole or slot in the material. Pin punches are commonly used in automotive, construction, and maintenance industries for disassembling and repairing machinery and equipment. Specifications: Material: Hardened and Ground Steel Standard: Imperial Set Includes: 5 Long Drive Pin Punches 8 Short Drive Pin Punches Length: Long Punches: Various lengths for deeper reach Short Punches: Compact sizes for tight spaces Tip Diameters: Precision sizes for various pin diameters Features: Durable Construction: Each punch is made from hardened and ground steel, offering exceptional strength and wear resistance. Precision Tips: Precisely ground tips ensure accurate alignment and insertion of roll pins without causing damage. Variety of Sizes: The set includes both long and short punches, providing versatility for different tasks and accessibility in tight spaces. Ergonomic Design: Comfortable handles with knurled grips ensure a firm hold and reduce hand fatigue during prolonged use. Complete Kit: A comprehensive set that includes all necessary sizes for common pin and bolt catch tasks. Benefits: Versatile Use: Suitable for a wide range of applications including firearm assembly, machinery maintenance, and various DIY projects. Enhanced Precision: Precisely machined tips prevent slipping and marring, ensuring professional results. Accessibility: Long punches provide extended reach for deeper or hard-to-access areas, while short punches are perfect for confined spaces. Durability: High-quality materials and construction ensure long-lasting performance even with frequent use. Convenient Storage: The set comes with an organized storage case, keeping your tools readily accessible and protected. Applications: Ideal for gunsmithing, including installing and removing roll pins in firearms. Useful for machinery maintenance, allowing precise insertion and removal of pins and bolts. Perfect for various DIY and home repair projects that require accurate pin driving. Usage Instructions: Select the appropriate punch from the set based on the size of the roll pin or bolt catch. Position the tip of the punch on the pin, ensuring it is aligned correctly. Strike the punch with a hammer to drive the pin in or out of the material. Use long punches for hard-to-reach areas and short punches for tight spaces. Set Components: Long Drive Pin Punches (5 Pcs): Sizes: 1/8", 3/16", 1/4", 5/16" 3/8", Short Drive Pin Punches (8 Pcs): Sizes: 1/16”, 3/32”, 1/8”, 5/32”, 3/16”, 7/32”, 1/4” & 5/16"

$24.50 $19.99

-

Buyohlic Automatic Center Punch with Replaceable Hardened Steel Tip

An automatic center punch is used to create a small indentation or mark on a surface with precision and minimal effort. It helps to accurately position drill bits, taps, or screws on metal, wood, or plastic surfaces before drilling, tapping, or fastening. This tool eliminates the need for a hammer, as it automatically applies sufficient force to create the mark or dimple. Specifications: Tip Material: Replaceable Hardened Steel Body Material: High-Quality Steel Dimension: Approximately 4-7/8" Long x 1/2" Diameter Tip Point Diameter: 0.055 Inches (1.4 mm ) Duty Options: Medium Duty, Heavy Duty Features: Automatic Action: Spring-loaded mechanism delivers a controlled impact for precise marking without the need for a hammer. Replaceable Tip: Hardened steel tip is replaceable, ensuring longevity and maintaining sharpness for accurate markings over time. Durable Construction: Made from high-quality steel or brass, the body is built to withstand regular use and resist corrosion. Ergonomic Design: The tool is designed for comfortable handling, reducing hand fatigue during extended use. Adjustable Force: Some models feature adjustable impact force, allowing customization based on the material and specific requirements. Benefits: Ease of Use: Automatically delivers a punch with a single hand operation, increasing efficiency and ease of use. Consistent Performance: Ensures uniform indentations for accurate drilling and prevents drill bits from slipping. Versatility: Suitable for use on various materials including metal, wood, plastic, and more. Cost-Effective: Replaceable tip extends the tool's life, providing long-term value. Enhanced Control: Ergonomic handle and adjustable force (if available) offer better control and precision in marking. Applications: Ideal for woodworking, metalworking, and general DIY projects. Suitable for marking drill spots on metal, wood, plastic, and other materials. Perfect for both professional use in industrial settings and home workshops. Usage Instructions: Position the tip of the punch on the material where you want to create an indentation. Press down firmly until the internal spring mechanism releases and creates a mark. For models with adjustable force, set the desired impact strength before use. Replace the hardened steel tip as needed to maintain optimal performance. Available Duty Options: Medium Duty: Suitable for general use on a variety of materials, offering a balance of precision and impact strength. Heavy Duty: Designed for tougher materials and more demanding applications, providing greater impact force for deeper indentations.

$16.10 - $31.40

-

Set of 5 Pcs Center Punch-Imperial Standard Hard Metal-Wood Working Hand Tools

Use of product- A center punch is used to create a small indentation or mark on a workpiece, typically metal, to accurately guide a drill bit or other tool for drilling or machining operations. It helps ensure that the drill bit starts in the correct position and prevents it from slipping. Specifications: Material: High-Quality Hard Metal Standard: Imperial Set Includes: 5 Center Punches Head Types: Square Head, Round Head Sizes range: 1/16" to 5/32" Tip Diameter: Precision ground tips for accurate marking Features: Durable Construction: Made from hardened steel, these center punches are built to withstand heavy use and provide long-lasting performance. Precision Tips: Each punch features a precisely ground tip that creates accurate, clear indentations for drilling. Versatile Head Designs: The set includes both square and round head punches, catering to different preferences and applications. Ergonomic Design: The punches are designed for comfortable handling, reducing user fatigue during prolonged use. Variety of Sizes: The set includes punches of various lengths and tip diameters, suitable for different materials and project requirements. Benefits: Accurate Drilling: Prevent drill bits from slipping and ensure precise hole placement with clearly marked indentations. Enhanced Control: The ergonomic handles provide a firm grip, allowing for controlled and effective use. Versatility: Suitable for use on a variety of materials, including metal, wood, and plastic, making it an invaluable tool set for any workshop. Professional Quality: Designed to meet the needs of both professional craftsmen and DIY enthusiasts, ensuring reliable performance in all applications. Applications: Ideal for woodworking, metalworking, and various DIY projects. Suitable for marking drill spots on metal, wood, plastic, and other materials. Perfect for both professional use in industrial settings and home workshops. Available Head Types: Square Head: Provides a larger striking surface and is less likely to roll off surfaces, ensuring stability. Round Head: Offers a comfortable grip and is easy to handle, ideal for more delicate or detailed work. {Internal Reference: HM}

$11.99 $11.70

-

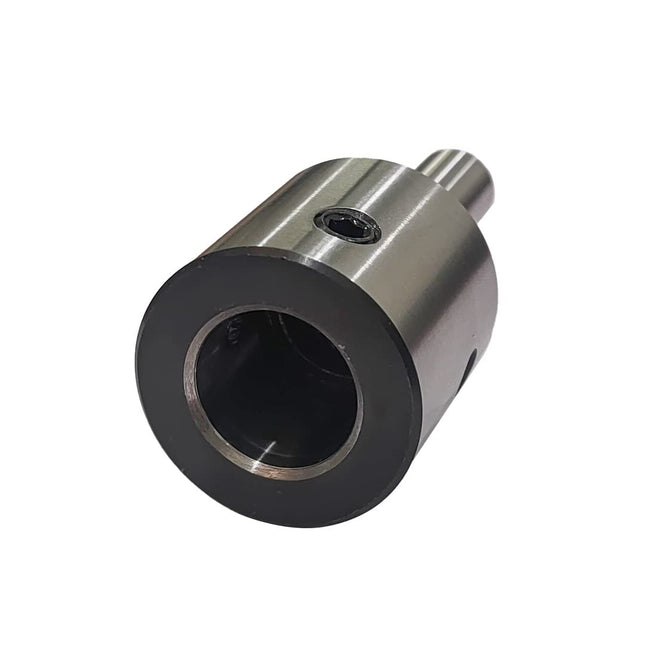

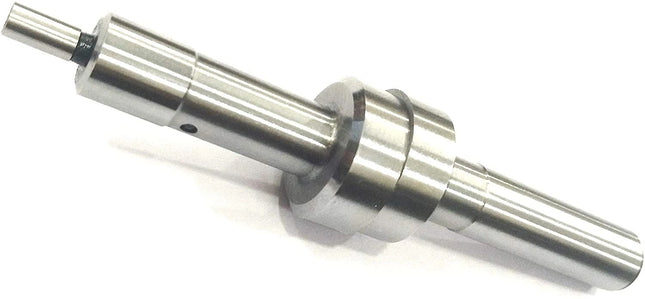

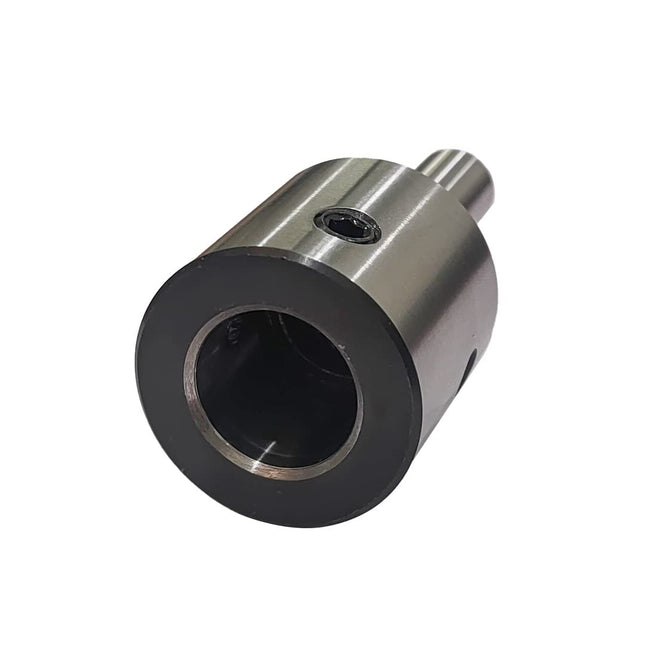

Annular Cutter 1/2" Shank Tool Steel Holder (Hard & Ground) with Lock Screw Tool

Annular cutter 1/2" shank tool steel holder (Rota broaches) with lock screw- Accepts/ suit 19 mm shank rota broaches An annular cutter is a tool used to make clean and precise holes in metal. It's like a specialized drill bit, but instead of removing material throughout the hole's length, it only cuts around the edge, leaving a solid center. This results in faster and more efficient hole-making, especially in metals like steel. It's commonly used in metalworking industries for tasks like installing pipes, cables, or creating openings for bolts. Superior Cutting Efficiency: Engineered for exceptional performance, our annular cutter set effortlessly drills through metal with precision and speed, reducing cutting times and boosting productivity. Durable Construction: Crafted from high grade alloy steel for durability and longevity, our annular cutters withstand the rigors of heavy-duty use, ensuring consistent performance even in demanding applications. Precision Machining: Each cutter is precision-ground to exacting standards, resulting in clean, accurate holes with minimal burrs or distortion, saving you time and effort in post-processing work. Versatile Compatibility: Compatible with most magnetic drill presses and annular cutting machines, our cutter set offers versatility and convenience, making it suitable for a wide range of metalworking tasks. Optimized Design: Featuring a unique geometry and cutting edge design, our annular cutters deliver optimal chip evacuation and reduced friction, resulting in smoother drilling and extended tool life. Comprehensive Set: Our set includes a range of popular sizes, ensuring you have the right cutter for various hole diameters, eliminating the need for multiple tool purchases and streamlining your workflow. Convenient Storage Case: Keep your cutters organized and easily accessible with the included storage case, featuring labeled compartments for quick identification and hassle-free transport to job sites. Tool Specifications:- Design 1 Holder dimensions: Shank 12.5 mm (*through bore 7 mm) , OAL: 62 mm, Holder body diameter: 36 mm, ID to hold cutter's shank 19.05 mm, Depth for holding cutter's hank : 25 mm, 2 x grub screw @ 90 degree for clamping of cutter's shank Design 2 Holder dimensions: Shank 12.5 mm, OAL: 75mm, Holder body diameter: 34 mm, ID to hold cutter's shank 19.05 mm, Depth for holding cutter's hank : 25 mm, 2 x grub screw @ 90 degree for clamping of cutter's shank {Internal Reference; HM}

$31.50 - $35.99

-

Set of 4 Pcs Pin Chuck Collet Vise Vice- Metric Capacity 0-4 MM

A pin chuck is a small, handy tool used primarily in woodworking and metalworking. It's essentially a miniature hand-held chuck that holds very small drill bits, taps, or other rotary tools securely. Pin chucks are particularly useful for delicate work where precision and control are necessary, such as jewelry making, model building, or fine detailing in woodworking. They allow the user to manually rotate and guide the tool with precision, making them suitable for intricate tasks where power tools might be too forceful or unwieldy. Set Includes: 4 precision pin chuck collet vises with varying capacities. Individual capacities: 0-0.8mm 0.8-1.3mm 1.3-3.1mm 3.1-4.8mm Material: High-quality hardened steel for durability and longevity. Corrosion-resistant finish to prevent rust and wear. Design & Construction: Ergonomic design for comfortable handling and precise control. Knurled bodies for a firm grip and easy tightening/loosening. Smooth and accurate threading ensures a secure fit for small drill bits, reamers, and other small tools. Versatility: Ideal for intricate and delicate work such as jewelry making, model building, electronics, and other crafts. Suitable for holding small tools with precision in various applications. Compatible with hand drills, drill presses, and rotary tools. Precision: Designed for high precision and accuracy in holding small diameter tools. Ensures stable and centered positioning to reduce run-out and improve work quality. Ease of Use: Easy to interchange collets for quick adjustments based on tool size. Lightweight and compact design for convenient storage and portability. Applications: Perfect for hobbyists, artisans, engineers, and professionals requiring detailed and accurate work. Ideal for drilling, reaming, and other precision tasks in various materials like metal, wood, and plastic. Dimensions: Compact size making it easy to handle and store. Each collet vise is precisely machined to ensure a tight and reliable hold. Additional Features: Comes in a protective case for easy organization and transport. Clear labeling of each collet size for quick identification. Quality Assurance: Backed by a satisfaction guarantee for peace of mind. Rigorous quality control to ensure consistency and performance. This set of 4 pin chuck collet vises provides a comprehensive solution for holding small diameter tools with precision and reliability. Perfect for detailed and delicate work, this set is an essential addition to any craftsman's toolkit. {Internal Reference: HM}

$12.95 $11.50

-

Edge Finder 10 mm / 0.200" Diameter Shank 4 mm Machine Measuring Tool

Use of product- An edge finder is a handy tool in machining, particularly in milling operations. Its primary purpose is to precisely locate the edges of a workpiece or the center of a hole. It works by being mounted in the spindle of the milling machine and brought into contact with the edge or surface being located. When the edge finder makes contact, it shifts slightly off-center, indicating the exact location. This helps machinists align their cutting tools accurately, ensuring that they begin machining at the correct position, thus improving precision and reducing errors in the manufacturing process. Features: Comprehensive Set: Includes four edge finders: EF-130, EF-132, EF-133, and EF-134, providing versatility for various milling tasks. Each edge finder is specifically designed to tackle different applications, ensuring you have the right tool for the job. Precision Machining: Enables accurate and repeatable positioning of the workpiece. Enhances the quality and precision of your milling operations. High-Quality Material: Made from premium, hardened steel for durability and long-lasting performance. Resistant to wear and corrosion, ensuring reliable use over time. Ease of Use: Simple and intuitive to use, making it suitable for both beginners and experienced machinists. Clearly marked for easy identification and selection. Versatile Application: Ideal for locating edges, shoulders, grooves, center points, and other critical points in milling and machining tasks. Suitable for use with a wide range of milling machines and CNC machines. Compact and Organized: Comes in a compact storage case, keeping the edge finders organized and protected. Easy to store and transport, minimizing workspace clutter. Specifications: Shank is 10 mm /.200" diameter with 4 mm probe Usage Instructions: Setup: Insert the desired edge finder into the collet or chuck of your milling machine or CNC machine. Alignment: Bring the edge finder close to the workpiece surface. Edge Finding: Rotate the edge finder and carefully bring it into contact with the workpiece. The edge finder will jump or move slightly when it touches the edge, indicating the position. Machining: Once the edge is located, proceed with the milling or machining operation, ensuring precise alignment. Applications: Suitable for metalworking, woodworking, and precision machining tasks. Ideal for use in manufacturing, repair workshops, and DIY projects. Benefits: Provides a comprehensive solution for precise edge finding and alignment. Enhances accuracy and efficiency in milling operations. Durable and reliable tools for long-term use. Equip your milling machine with the 4 Pieces Edge Finder Set today and achieve unparalleled precision and efficiency in your machining tasks. {Internal Reference: HM}

$9.90 $9.00

-

Set Of 5 Piece Edge Finders Set -Hardened Tool Steel/Imperial Standard

An edge finder is a handy tool in machining, particularly in milling operations. Its primary purpose is to precisely locate the edges of a workpiece or the center of a hole. It works by being mounted in the spindle of the milling machine and brought into contact with the edge or surface being located. When the edge finder makes contact, it shifts slightly off-center, indicating the exact location. This helps machinists align their cutting tools accurately, ensuring that they begin machining at the correct position, thus improving precision and reducing errors in the manufacturing process. Features: Comprehensive Set: Includes four edge finders: EF-130, EF-132, EF-133, and EF-134, providing versatility for various milling tasks. Each edge finder is specifically designed to tackle different applications, ensuring you have the right tool for the job. Precision Machining: Enables accurate and repeatable positioning of the workpiece. Enhances the quality and precision of your milling operations. High-Quality Material: Made from premium, hardened steel for durability and long-lasting performance. Resistant to wear and corrosion, ensuring reliable use over time. Ease of Use: Simple and intuitive to use, making it suitable for both beginners and experienced machinists. Clearly marked for easy identification and selection. Versatile Application: Ideal for locating edges, shoulders, grooves, center points, and other critical points in milling and machining tasks. Suitable for use with a wide range of milling machines and CNC machines. Compact and Organized: Comes in a compact storage case, keeping the edge finders organized and protected. Easy to store and transport, minimizing workspace clutter Specifications: Double End Type: Double End TIP Diameter: 1/2" Tip Diameter: 3/16' Features: Standard edge finder for general use Single End Type: Single End Tip Diameter: 3/8" Inch Tip Diameter: 3/16" Usage Instructions: Setup: Insert the desired edge finder into the collet or chuck of your milling machine or CNC machine. Alignment: Bring the edge finder close to the workpiece surface. Edge Finding: Rotate the edge finder and carefully bring it into contact with the workpiece. The edge finder will jump or move slightly when it touches the edge, indicating the position. Machining: Once the edge is located, proceed with the milling or machining operation, ensuring precise alignment. Package Includes: 2 x Double End Edge Finder 3 x Single End Edge Finder 1 x Compact Storage Case Applications: Suitable for metalworking, woodworking, and precision machining tasks. Ideal for use in manufacturing, repair workshops, and DIY projects. Benefits: Provides a comprehensive solution for precise edge finding and alignment. Enhances accuracy and efficiency in milling operations. Durable and reliable tools for long-term use. Equip your milling machine with the 4 Pieces Edge Finder Set today and achieve unparalleled precision and efficiency in your machining tasks. {Internal Reference: HM}

$34.50 $24.95

-

Tool Steel Quality 4 Pieces Edge Finder Set Includes EF-130, 132, 133, 134

An edge finder is a handy tool in machining, particularly in milling operations. Its primary purpose is to precisely locate the edges of a workpiece or the center of a hole. It works by being mounted in the spindle of the milling machine and brought into contact with the edge or surface being located. When the edge finder makes contact, it shifts slightly off-center, indicating the exact location. This helps machinists align their cutting tools accurately, ensuring that they begin machining at the correct position, thus improving precision and reducing errors in the manufacturing process. Features: Comprehensive Set: Includes four edge finders: EF-130, EF-132, EF-133, and EF-134, providing versatility for various milling tasks. Each edge finder is specifically designed to tackle different applications, ensuring you have the right tool for the job. Precision Machining: Enables accurate and repeatable positioning of the workpiece. Enhances the quality and precision of your milling operations. High-Quality Material: Made from premium, hardened steel for durability and long-lasting performance. Resistant to wear and corrosion, ensuring reliable use over time. Ease of Use: Simple and intuitive to use, making it suitable for both beginners and experienced machinists. Clearly marked for easy identification and selection. Versatile Application: Ideal for locating edges, shoulders, grooves, center points, and other critical points in milling and machining tasks. Suitable for use with a wide range of milling machines and CNC machines. Compact and Organized: Comes in a compact storage case, keeping the edge finders organized and protected. Easy to store and transport, minimizing workspace clutter. Specifications: EF-130: Type: Single End Shank Diameter: 1/2" Tip Dia: 1/2" Features: Standard edge finder for general use EF-132: Type: Double End Shank Diameter: 1/2" Inch Tip Diameter: 1/2", 0.2" Features: Includes a ball and cylinder for versatile edge finding EF-133: Type: Single End Shank Diameter: 3/8" Inches Tip Diameter: 0.2" Features: Designed for small and delicate workpieces EF-134: Type: Double End Shank Diameter: 1/2" Inch Tip Diameter: 2" Tip, Point Features: Enhanced precision for fine edge finding Usage Instructions: Setup: Insert the desired edge finder into the collet or chuck of your milling machine or CNC machine. Alignment: Bring the edge finder close to the workpiece surface. Edge Finding: Rotate the edge finder and carefully bring it into contact with the workpiece. The edge finder will jump or move slightly when it touches the edge, indicating the position. Machining: Once the edge is located, proceed with the milling or machining operation, ensuring precise alignment. Package Includes: 1 x EF-130 Edge Finder 1 x EF-132 Edge Finder 1 x EF-133 Edge Finder 1 x EF-134 Edge Finder 1 x Compact Storage Case Applications: Suitable for metalworking, woodworking, and precision machining tasks. Ideal for use in manufacturing, repair workshops, and DIY projects. Benefits: Provides a comprehensive solution for precise edge finding and alignment. Enhances accuracy and efficiency in milling operations. Durable and reliable tools for long-term use. Equip your milling machine with the 4 Pieces Edge Finder Set today and achieve unparalleled precision and efficiency in your machining tasks. {Internal Reference: HM}

$19.90 $16.16

-

Wiggler & Center finder Set Work Edge Centre Finding Run out concentrical align 5 Pcs Set

A wiggler and center finder set is a tool used in machining and metalworking to precisely locate the center of a workpiece or machine spindle. The wiggler, also known as a center finder, is a small, spring-loaded tool with a pointed tip that wiggles or oscillates when touched against a surface. This oscillation helps identify the exact center point of a hole or edge. Key Features High Precision: Ensures accurate alignment and positioning of workpieces. Ideal for setting up workpieces on milling machines and lathes. Versatile Set: Typically includes multiple attachments for various tasks: ball probe, disc probe, needle point, and offset indicator holder. Suitable for finding centers, edges, and hole locations. Durable Construction: Made from high-quality, hardened tool steel for long-lasting durability. Resistant to wear, ensuring consistent performance over time. Easy to Use: Simple setup process, making it accessible for both novice and experienced machinists. Clear and sharp graduations for easy reading and precise adjustments. Compact Storage: Comes with a sturdy storage case to keep all components organized and protected. Portable design for easy transport between workstations. Enhanced Accuracy: Helps achieve precise machining operations, improving overall work quality. Reduces setup time and increases efficiency in machining tasks. Benefits Improved Accuracy: Enables precise alignment and positioning, leading to higher quality machining results. Versatility: Can be used for a variety of tasks including centering, edge finding, and hole location. Durability: Built to last with high-quality materials that withstand regular use in a workshop environment. Ease of Use: User-friendly design with clear graduations and easy-to-change attachments. Organization: Comes with a storage case to keep all pieces together and protected, ensuring longevity and ease of access. Specifications Material: tool steel Number of Pieces: Typically 5 pieces (ball probe, disc probe, needle point, offset indicator holder, storage case) Accuracy: High precision with minimal deviation Package Includes Ball probe attachment Disc probe attachment Needle point attachment Offset indicator holder Sturdy storage case Ideal For Machinists Metalworkers Engineers Toolmakers Hobbyists and DIY enthusiasts Additional Notes Regularly clean and maintain the wiggler set to ensure optimal performance and accuracy. Store all components in the provided case to prevent loss and damage. Always handle with care to avoid bending or damaging the precision attachments.

$13.99 $11.61