Edge Finders

-

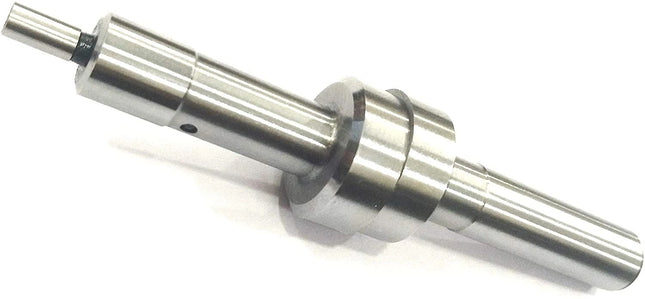

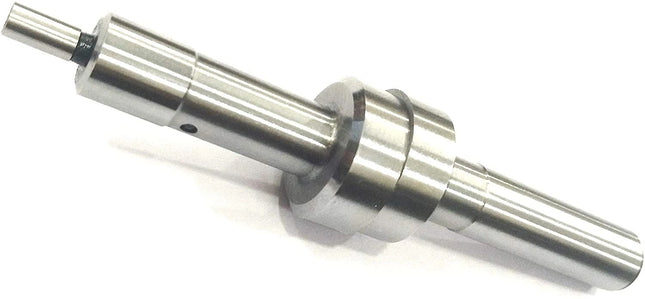

Edge Finder 10 mm / 0.200" Diameter Shank 4 mm Machine Measuring Tool

Use of product- An edge finder is a handy tool in machining, particularly in milling operations. Its primary purpose is to precisely locate the edges of a workpiece or the center of a hole. It works by being mounted in the spindle of the milling machine and brought into contact with the edge or surface being located. When the edge finder makes contact, it shifts slightly off-center, indicating the exact location. This helps machinists align their cutting tools accurately, ensuring that they begin machining at the correct position, thus improving precision and reducing errors in the manufacturing process. Features: Comprehensive Set: Includes four edge finders: EF-130, EF-132, EF-133, and EF-134, providing versatility for various milling tasks. Each edge finder is specifically designed to tackle different applications, ensuring you have the right tool for the job. Precision Machining: Enables accurate and repeatable positioning of the workpiece. Enhances the quality and precision of your milling operations. High-Quality Material: Made from premium, hardened steel for durability and long-lasting performance. Resistant to wear and corrosion, ensuring reliable use over time. Ease of Use: Simple and intuitive to use, making it suitable for both beginners and experienced machinists. Clearly marked for easy identification and selection. Versatile Application: Ideal for locating edges, shoulders, grooves, center points, and other critical points in milling and machining tasks. Suitable for use with a wide range of milling machines and CNC machines. Compact and Organized: Comes in a compact storage case, keeping the edge finders organized and protected. Easy to store and transport, minimizing workspace clutter. Specifications: Shank is 10 mm /.200" diameter with 4 mm probe Usage Instructions: Setup: Insert the desired edge finder into the collet or chuck of your milling machine or CNC machine. Alignment: Bring the edge finder close to the workpiece surface. Edge Finding: Rotate the edge finder and carefully bring it into contact with the workpiece. The edge finder will jump or move slightly when it touches the edge, indicating the position. Machining: Once the edge is located, proceed with the milling or machining operation, ensuring precise alignment. Applications: Suitable for metalworking, woodworking, and precision machining tasks. Ideal for use in manufacturing, repair workshops, and DIY projects. Benefits: Provides a comprehensive solution for precise edge finding and alignment. Enhances accuracy and efficiency in milling operations. Durable and reliable tools for long-term use. Equip your milling machine with the 4 Pieces Edge Finder Set today and achieve unparalleled precision and efficiency in your machining tasks. {Internal Reference: HM}

$9.90 $9.50

-

Set Of 5 Piece Edge Finders Set -Hardened Tool Steel/Imperial Standard

An edge finder is a handy tool in machining, particularly in milling operations. Its primary purpose is to precisely locate the edges of a workpiece or the center of a hole. It works by being mounted in the spindle of the milling machine and brought into contact with the edge or surface being located. When the edge finder makes contact, it shifts slightly off-center, indicating the exact location. This helps machinists align their cutting tools accurately, ensuring that they begin machining at the correct position, thus improving precision and reducing errors in the manufacturing process. Features: Comprehensive Set: Includes four edge finders: EF-130, EF-132, EF-133, and EF-134, providing versatility for various milling tasks. Each edge finder is specifically designed to tackle different applications, ensuring you have the right tool for the job. Precision Machining: Enables accurate and repeatable positioning of the workpiece. Enhances the quality and precision of your milling operations. High-Quality Material: Made from premium, hardened steel for durability and long-lasting performance. Resistant to wear and corrosion, ensuring reliable use over time. Ease of Use: Simple and intuitive to use, making it suitable for both beginners and experienced machinists. Clearly marked for easy identification and selection. Versatile Application: Ideal for locating edges, shoulders, grooves, center points, and other critical points in milling and machining tasks. Suitable for use with a wide range of milling machines and CNC machines. Compact and Organized: Comes in a compact storage case, keeping the edge finders organized and protected. Easy to store and transport, minimizing workspace clutter Specifications: Double End Type: Double End TIP Diameter: 1/2" Tip Diameter: 3/16' Features: Standard edge finder for general use Single End Type: Single End Tip Diameter: 3/8" Inch Tip Diameter: 3/16" Usage Instructions: Setup: Insert the desired edge finder into the collet or chuck of your milling machine or CNC machine. Alignment: Bring the edge finder close to the workpiece surface. Edge Finding: Rotate the edge finder and carefully bring it into contact with the workpiece. The edge finder will jump or move slightly when it touches the edge, indicating the position. Machining: Once the edge is located, proceed with the milling or machining operation, ensuring precise alignment. Package Includes: 2 x Double End Edge Finder 3 x Single End Edge Finder 1 x Compact Storage Case Applications: Suitable for metalworking, woodworking, and precision machining tasks. Ideal for use in manufacturing, repair workshops, and DIY projects. Benefits: Provides a comprehensive solution for precise edge finding and alignment. Enhances accuracy and efficiency in milling operations. Durable and reliable tools for long-term use. Equip your milling machine with the 4 Pieces Edge Finder Set today and achieve unparalleled precision and efficiency in your machining tasks. {Internal Reference: HM}

$34.50 $31.50

-

Tool Steel Quality 4 Pieces Edge Finder Set Includes EF-130, 132, 133, 134

An edge finder is a handy tool in machining, particularly in milling operations. Its primary purpose is to precisely locate the edges of a workpiece or the center of a hole. It works by being mounted in the spindle of the milling machine and brought into contact with the edge or surface being located. When the edge finder makes contact, it shifts slightly off-center, indicating the exact location. This helps machinists align their cutting tools accurately, ensuring that they begin machining at the correct position, thus improving precision and reducing errors in the manufacturing process. Features: Comprehensive Set: Includes four edge finders: EF-130, EF-132, EF-133, and EF-134, providing versatility for various milling tasks. Each edge finder is specifically designed to tackle different applications, ensuring you have the right tool for the job. Precision Machining: Enables accurate and repeatable positioning of the workpiece. Enhances the quality and precision of your milling operations. High-Quality Material: Made from premium, hardened steel for durability and long-lasting performance. Resistant to wear and corrosion, ensuring reliable use over time. Ease of Use: Simple and intuitive to use, making it suitable for both beginners and experienced machinists. Clearly marked for easy identification and selection. Versatile Application: Ideal for locating edges, shoulders, grooves, center points, and other critical points in milling and machining tasks. Suitable for use with a wide range of milling machines and CNC machines. Compact and Organized: Comes in a compact storage case, keeping the edge finders organized and protected. Easy to store and transport, minimizing workspace clutter. Specifications: EF-130: Type: Single End Shank Diameter: 1/2" Tip Dia: 1/2" Features: Standard edge finder for general use EF-132: Type: Double End Shank Diameter: 1/2" Inch Tip Diameter: 1/2", 0.2" Features: Includes a ball and cylinder for versatile edge finding EF-133: Type: Single End Shank Diameter: 3/8" Inches Tip Diameter: 0.2" Features: Designed for small and delicate workpieces EF-134: Type: Double End Shank Diameter: 1/2" Inch Tip Diameter: 2" Tip, Point Features: Enhanced precision for fine edge finding Usage Instructions: Setup: Insert the desired edge finder into the collet or chuck of your milling machine or CNC machine. Alignment: Bring the edge finder close to the workpiece surface. Edge Finding: Rotate the edge finder and carefully bring it into contact with the workpiece. The edge finder will jump or move slightly when it touches the edge, indicating the position. Machining: Once the edge is located, proceed with the milling or machining operation, ensuring precise alignment. Package Includes: 1 x EF-130 Edge Finder 1 x EF-132 Edge Finder 1 x EF-133 Edge Finder 1 x EF-134 Edge Finder 1 x Compact Storage Case Applications: Suitable for metalworking, woodworking, and precision machining tasks. Ideal for use in manufacturing, repair workshops, and DIY projects. Benefits: Provides a comprehensive solution for precise edge finding and alignment. Enhances accuracy and efficiency in milling operations. Durable and reliable tools for long-term use. Equip your milling machine with the 4 Pieces Edge Finder Set today and achieve unparalleled precision and efficiency in your machining tasks. {Internal Reference: HM}

$19.90 $17.90

-

Wiggler & Center finder Set Work Edge Centre Finding Run out concentrical align 5 Pcs Set

A wiggler and center finder set is a tool used in machining and metalworking to precisely locate the center of a workpiece or machine spindle. The wiggler, also known as a center finder, is a small, spring-loaded tool with a pointed tip that wiggles or oscillates when touched against a surface. This oscillation helps identify the exact center point of a hole or edge. Key Features High Precision: Ensures accurate alignment and positioning of workpieces. Ideal for setting up workpieces on milling machines and lathes. Versatile Set: Typically includes multiple attachments for various tasks: ball probe, disc probe, needle point, and offset indicator holder. Suitable for finding centers, edges, and hole locations. Durable Construction: Made from high-quality, hardened tool steel for long-lasting durability. Resistant to wear, ensuring consistent performance over time. Easy to Use: Simple setup process, making it accessible for both novice and experienced machinists. Clear and sharp graduations for easy reading and precise adjustments. Compact Storage: Comes with a sturdy storage case to keep all components organized and protected. Portable design for easy transport between workstations. Enhanced Accuracy: Helps achieve precise machining operations, improving overall work quality. Reduces setup time and increases efficiency in machining tasks. Benefits Improved Accuracy: Enables precise alignment and positioning, leading to higher quality machining results. Versatility: Can be used for a variety of tasks including centering, edge finding, and hole location. Durability: Built to last with high-quality materials that withstand regular use in a workshop environment. Ease of Use: User-friendly design with clear graduations and easy-to-change attachments. Organization: Comes with a storage case to keep all pieces together and protected, ensuring longevity and ease of access. Specifications Material: tool steel Number of Pieces: Typically 5 pieces (ball probe, disc probe, needle point, offset indicator holder, storage case) Accuracy: High precision with minimal deviation Package Includes Ball probe attachment Disc probe attachment Needle point attachment Offset indicator holder Sturdy storage case Ideal For Machinists Metalworkers Engineers Toolmakers Hobbyists and DIY enthusiasts Additional Notes Regularly clean and maintain the wiggler set to ensure optimal performance and accuracy. Store all components in the provided case to prevent loss and damage. Always handle with care to avoid bending or damaging the precision attachments.

$13.99 $12.50